Oyster mushroom cultivation

Author: Anna Szabó

Substrate

Oyster mushrooms (Pleurotus spp.) are so called white rot mushrooms, which means that they are able to degrade not only hemicelluloses and cellulose but lignin as well, therefore many agricultural byproducts and wastes (e.g. stems, leafs, peels, corn cob, wood chip, sawdust, trunk etc.) can be used as substrates in oyster cultivation. Oysters require more carbon and less nitrogen in the substrate than button mushrooms. The C:N rate of wheat straw is 100:1, which is good for oysters. In extensive oyster cultivation trunks are used as substrates.

Various materials (depending on the agriculture of a country and availability) can be used as substrate ingredients in intensive cultivation. In Hungary, wheat straw is the main ingredient, while in other countries byproducts of cotton cultivation and sugar production, different grains etc are used. Every material has to be free of diseases and pests, it has to be dry and healthy and originate from biologically mature plants. Any plant protection treatment and fertilization could influence the quality of the plant part, which could later become substrate.

Video: Oyster mushroom cultivation in the Netherlands

The supplementation used in button mushroom composts does not have the same positive effect if added to oyster substrates (See chapter 6). This derives from the fact that oysters are more sensitive to molds and other competitive fungi, which prefer nutrient rich substrates. Another problem caused by supplementation is that in summer a nutrient rich material could easily overheat, which leads to mycelium damage. Substrate producers are trying to find new products to supplement with (e.g. ChampFood “O”). These products are usually soy-based with an average 40% protein content and other ingredients that are not well-known.

Substrate preparation

Oyster mushrooms are cultivated on a specially manufactured material called substrate. Although it has the same role as the compost in button mushroom cultivation, their production process is not the same. Substrate is prepared by either with or without heat treatment.

In modern oyster mushroom cultivation technologies no substrates without some type of heat treatment are used. In extensive technologies trunks, logs, corn stem or cob or even wheat straw can be substrates of oyster mushrooms without any kind of sterilization or pasteurization, but in case of these materials the risk of diseases is high and the quality of the product is low.

Substrate preparation with heat treatment

In intensive oyster cultivation the ingredients of the growing media (substrate) are heat treated. The purpose of the heat treatment in substrate preparation is to reduce the number of competitive organisms, pests (eggs and larvae, eelworms or mites) and pathogens (spores and mycelia of different bacteria or fungi), to ensure optimal conditions for the mycelial development of the cultivated mushroom. There are more heat treatment technologies that are used nowadays in substrate preparation, for example sterilization, dry heat treatment or wet heat treatment.

Sterilization

The materials (corn cob, rice or wheat bran, sawdust etc.) are sterilized in high pressure and temperature to eliminate (not just reduce) the competitive organisms. Since not only the harmful organisms die, but also those agents that aid oyster mycelial growth, the material is more susceptible for infestations during the growing cycle. This method is used mainly in Eastern-Asia, but not common in Europe because of its high energy cost.

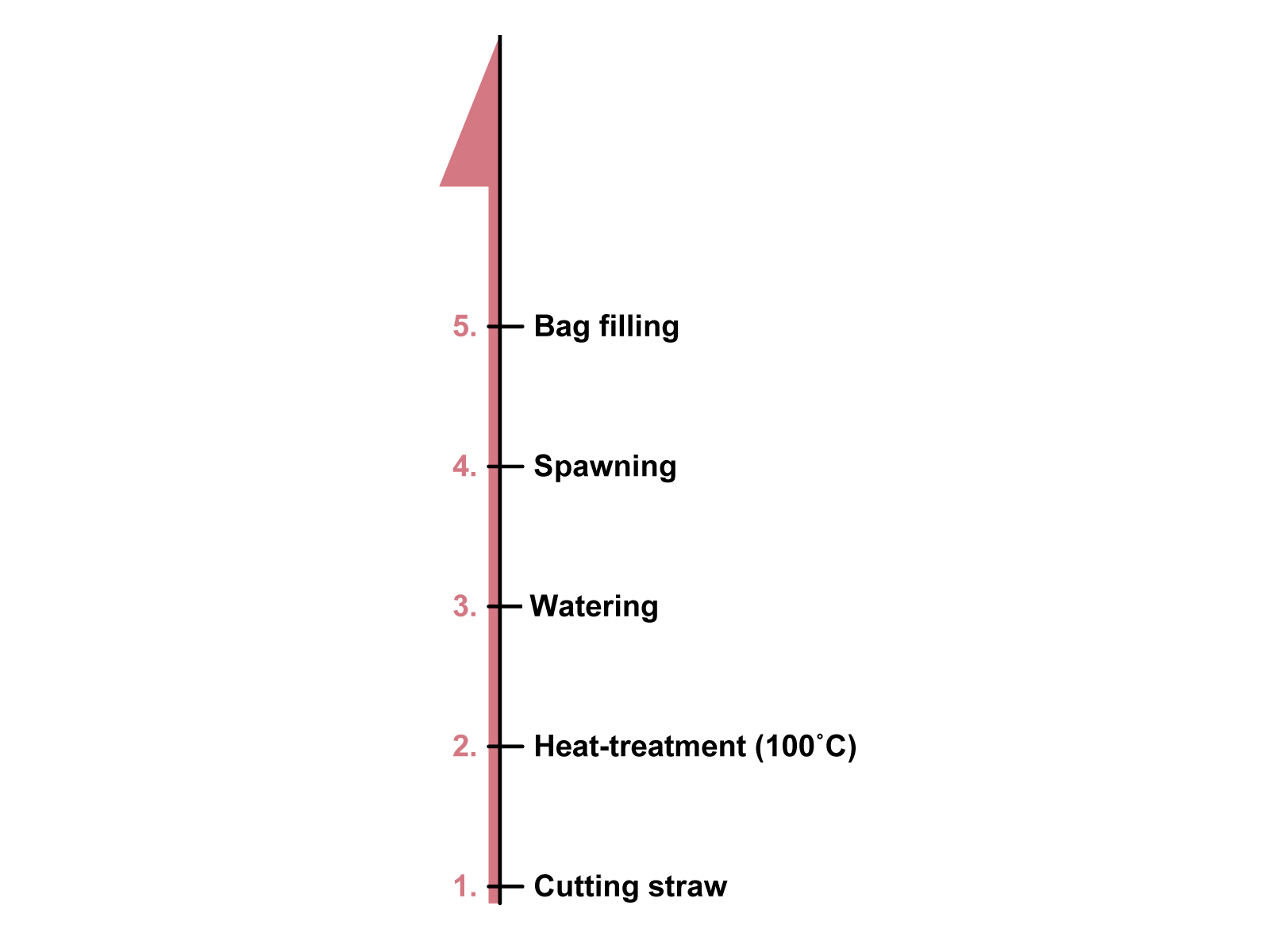

Dry heat treatment – xerotherm technology

Dry heat treatment is a common substrate preparation method in Hungary. First the wheat straw is ground to 1-3 cm pieces (this way the water absorption of the straw improves). Then the dry straw is filled into insulated chambers, where steam is added during a 60 minutes period. After the heat treatment material is not moisture enough (and the temperature is too high for spawning). That is why following heat treatment the straw is put on a conveyor belt and watered (until 65-75% water content) and cooled (less than 30˚C). Then spawn is added, which is (similar to button mushroom spawn) grain colonized by the mycelia of the oyster mushroom. The grain is usually millet, rye or wheat. 3-5 liter spawn is added to 100 kg substrate, than mixed and filled into perforated bags.

During watering on the conveyor belt, mould spores could get into the substrate. A few years ago the standard procedure was to add fungicides, but nowadays they are not allowed anymore, so hygiene became especially important. The rooms, tools, equipment and clothes are cleaned and sterilized for prevention.

Steps of substrate preparation with dry heat treatment

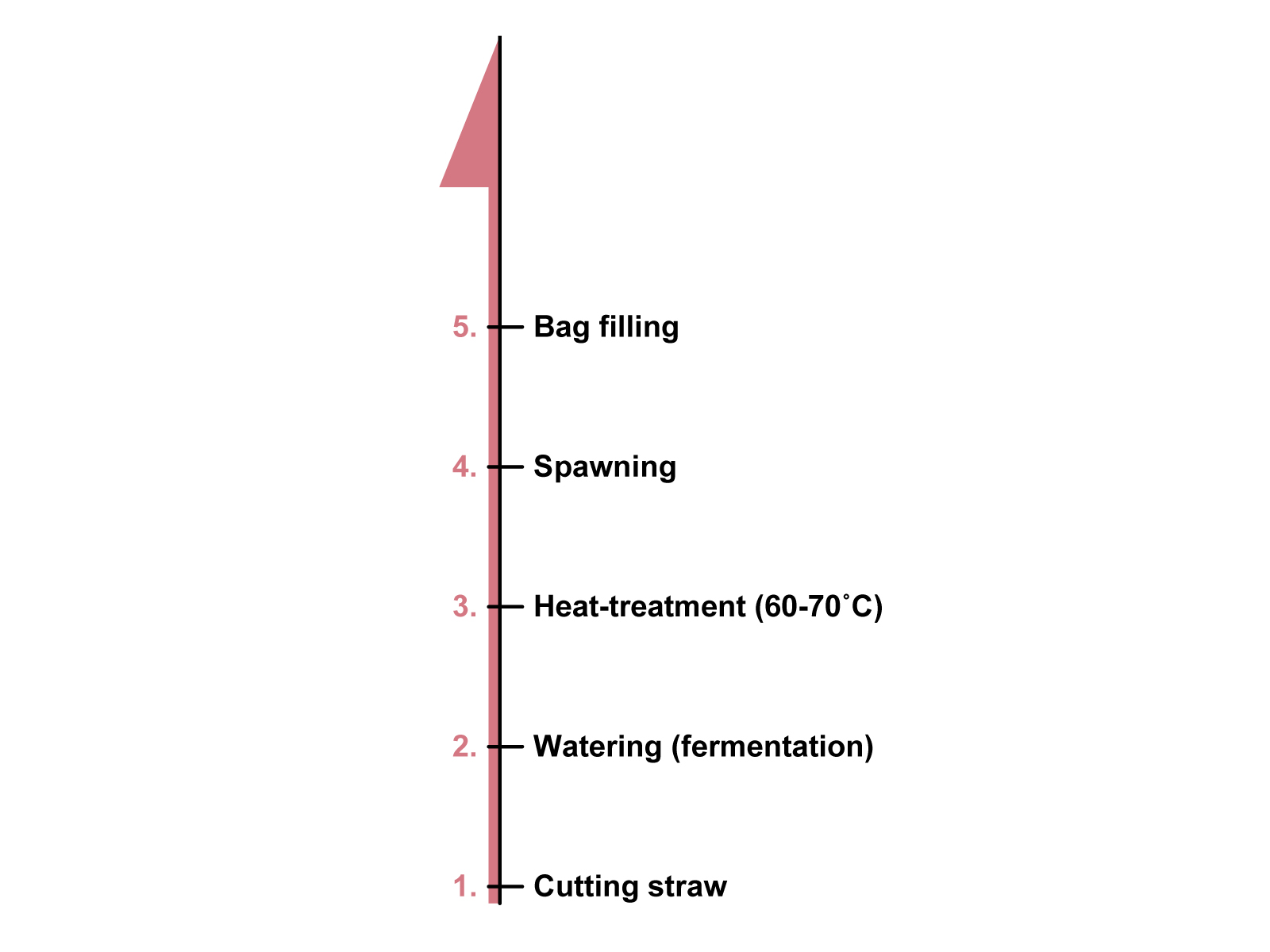

Wet heat treatment

Wet heat treatment (or otherwise known as fermentation or pasteurization) is the most common substrate preparation method in Hungary. It is more similar to the process of compost making. Unlike in case of the above presented dry technology, the wheat straw is watered (right after grounding) before heat treatment. The moisture content has to reach 70% before the straw is treated with steam.

Steps of substrate preparation with wet heat treatment

The material is than filled into heat treatment tunnels (just like the ones used in compost plants) and heated up first to 60-70˚C. On this temperature, in approx. 6 hours the competitive organisms die. This is followed by a 48 hour long conditioning on 50˚C, during which the useful microflora (that ensures protection against pathogens in the substrate) forms. Fresh has to be added in order to prevent anaerobic conditions. After the material is cooled, spawn is added and finally perforated bags are filled the substrate.

Substrate preparation by the Pilze-Nagy Ltd., Hungary

The largest producer (Pilze-Nagy Ltd.) in Hungary prepares substrate by wet heat treatment. Here another step (pre-fermentation) is added prior to the process. After grounding the straw, it is watered, piled up and occasionally turned for 3-7 days, during which pre-fermentation (breaking down of materials and heating up) commences. Only after this step is the material filled into the heat treating tunnels, where (due to the heat produced during pre-fermentation) no additional heating is necessary to reach the desirable 60-70˚C (which makes the procedure more cost effective). Finally the substrate is cooled by fresh air, then spawned and filled into bags.

Grounding, watering and pre-fermentation of the wheat straw

Other heat treatments

Substrate can be prepared by soaking in 60-80˚C water for 30-60 minutes, this way heating and raising moisture content is done at once. The disadvantage of this method is that although it lowers the number of pathogens, but in not efficient enough against pests. Another method is to soak the straw in cold water for days. This is used mainly in Eastern-Asia, but not in Europe. Besides the above mentioned technologies, no other methods are used in Hungary for commercial substrate preparation. Some other ways of substrate making are used by small scale growers, but usually only for their own purposes.

Oyster cultivation

Extensive cultivation

Oyster mushrooms used to be cultivated on wood, on trunks or logs. The substrate was never heat treated and cultivation took place outside. Nowadays this technology is called extensive cultivation and only done by small scale growers or by houses as a hobby. Wood of many species is suitable for the oyster mushroom, for example: beech (Fagus spp.), chestnut (Castanea spp.), maple (Acer spp.), hornbeam (Celtis spp.), poplar (Populus spp.), birch (Betula spp.), willow (Salix spp.) or walnut ( Juglans spp.), apple (Malus spp.) and pear (Pyrus spp.). Oak (Quercus spp.) and acacia (Robinia spp.) as well as pine species are not recommended.

Both the trunks and the logs of the above mentioned species can be used as long as the wood is healthy, free of tinder and its moisture level is at least 50%. The wood is cut into 30-40x20-30 cm pieces. Spawning can be done from spring until fall, since the optimal temperature for spawn run is 25-27˚C. Spawn is put into holes drilled multiple places in the wood, or in rare cases spread over the surface. The holes then sealed with wax, in order to prevent drying.

Trunk prepared for spawning

After spawning to ensure humidity and moisture conditions the wood has to be covered with plastic and soil. During spawn run the wood can either be left outside or taken into a cellar etc. Spawn run takes around 3-12 months to complete. By the end, the wood has a definite mushroom odor and the mycelia are visible on the surface. The logs and trunks are then taken outside and to ensure proper moisture content they are placed into the ground, so only the top third is visible. If the weather is dry, watering the area around the trunks and logs is necessary. Cropping starts in fall, when the night temperature is below 5-10˚C. Oyster mushroom is ready to pick in 5-6 days after the primordia appears. Cropping continues until the first winter frosts and starts again in the spring.

On softwood oyster grows for 3-4, while on hardwood for 4-5 years long. By the end of the 3-5 years period, the oyster breaks down the wood (which then falls apart). Although the costs of extensive oyster cultivation are relative low, the spawn run period is long and the yield is unsteady, so only small scale growers and families use this technology.

Intensive cultivation

Growing good quality and high quantity oyster mushroom can only be done by intensive technologies on heat treated substrate in modern growing houses. The principles of intensive oyster mushroom cultivation were developed based on the work of Hungarian researchers in the 1970’s.

Growing area, equipment

Oyster mushroom can be grown in cellars, in no longer used agricultural buildings and in special mushroom growing tents or houses.

Oyster cultivation in mushroom tents (Pilze-Nagy Ltd.)

Agricultural building prepared and disinfected for oyster growing (Pilze-Nagy Ltd.)

Semi-intensive oyster cultivation in a mushroom house

Like in case of button mushroom cultivation one of the most important requirement is that the ambient conditions (temperature, humidity, CO2 level) of the growing area could be adjusted through the cropping period. The rooms are usually heated by hot water running through pipes placed on the floor, or sometimes hot, humid air is ventilated. Compared to heating, cooling the rooms is more difficult to manage. For this purpose a so called humypad is used, which is a panel placed in one end of the growing room. Cold water is poured on the top, which then soaks through the entire panel. Through this wet surface a ventilator placed on the opposite end of the room sucks the humid, cooled air into the room. This equipment not only lowers the temperature, but ensures 75-85% relative humidity. Occasionally additional watering of the ground is necessary and humidifiers are used. When adding fresh air, it is important that the flow should be around 6-8 cm/second. Unlike button mushrooms, oysters require light (200-400 lux for around 8 hours a day) during cropping, otherwise the fruitbodies deform (the stem elongates and the caps get smaller) and the color changes.

Another requirement is sanitation. The growers have to be able to effectively clean and sterilize the growing area. Since no chemicals are allowed in oyster cultivation, the only option is prevention and following strict sanitary regulations.

Filling and spawn run

Before taking the substrate into the growing rooms, cleaning and sterilizing the surfaces and the equipment have to be done. The blocks can either be put where the cropping will be done, or put into rooms (spawn run rooms), where spawn run will complete and then moved to their final places. In spawn run rooms the bags are usually placed close to each other on the floor or on shelves.

Spawn run on shelves

The mycelial growth produces heat in the blocks, so if placed close together, the blocks heat each other and it is easier to ensure the optimal temperature (18-22˚C in the air and 25-27˚C in the substrate). In summer more space has to be left between the blocks in order to prevent overheating, or else (when the temperature gets higher than 30˚C) the mycelium gets damaged or dies. Thermometers have to be placed in the substrate for monitoring. Since the blocks are perforated, the substrate could dry if the air is not humid enough. That is why humidifiers have to operate and the floor has to be watered.

Spawn run is done in 2-3 weeks, depending on the temperature and how the blocks were filled with substrate (thick or loose). If the substrate is too loose, the mycelial growth is slower, since the mycelia have to grow through air between the wheat straw pieces. Additionally, a space forms between the substrate and the plastic, and instead of growing through the perforations, fruitbodies will appear under the plastic, not on the surface of the block. By the end of spawn run, the blocks become white.

The disadvantage of spawn run done in a different room than cropping, is that by the end of colonization the blocks have to be moved one additional time (manpower and plus work hours) and the cropping starts a few days later.

Cropping

Following the 2-3 weeks of colonization, the mycelia in the substrate is left for 7-10 days to strengthen and to prepare for starting the generative developmental stage after vegetative growth. By the end of this period primordia appears in the perforations of the block. From this point the blocks should not be moved or else the mycelia get damaged and the fruitbody formation is set back.

Primordia of oyster mushroom

In this 7-10 day period, to promote cropping the substrate temperature is lowered from 25-27˚C to 18˚C, while the relative humidity is kept around 90-95˚C to prevent the substrate to dry. If the CO2 level is higher than 1000 ppm, the stems of the fruitbodies elongate and the caps get smaller. As soon as cropping starts, the substrate temperature has to lowered to 10-17˚C. The optimal relative humidity is 75-80%. During the growing of the fruitbodies the culture needs more fresh air, but the flow should not be too fast and should not hit the blocks directly, or else it damages the fruitbodies. Oyster mushrooms need light for fruitbody formation, approx. 1000-1500 lux a day.

Block during cropping

Picking and packing

Most hybrid oyster varieties used nowadays for cultivation need 5-7 days to get the size suitable for picking, when the edge of the cap is not yet straight and the flesh is fresh rather than tough. When the fruitbodies are over matured, spores appear and cover the blocks. Oyster spores are allergenic, they cause coughing, fewer and flu-like symptoms, thus pickers have to be equipped with protective masks. One of the targets of breeding new varieties is to find sporeless strains. The first sporeless hybrids have been tested in cultivation. Results show that both the yield and the quality are lower than of those of the traditional strains. Like button mushrooms, oysters are picked manually as well. With a slight twist, the whole fruitbody is removed in one piece from the perforation. Any residue has to be removed, or else secondary bacterial and fungal diseases could occur.

Oyster mushroom in the growing room and in the kitchen (in Hungarian)

The substrate from the base of the fruitbody is removed (cut) before packing. Oyster mushrooms are sold in one piece or separated to individual fruitbodies. When sold individually, a short (2-3 cm long) stem is left, the rest is waste. Before packing, the mushroom is pre-cooled on 10˚C, than stored on 2˚C.

After picking, to facilitate mycelia regeneration and to induce the next flush, the temperature is set on 25-27˚C for a week. Then by lowering the temperature, increasing relative humidity and adding more fresh air, the next flush is induced. In intensive cultivation the first flush is 60-70%of the total yield, so usually only two flushes are picked. A cropping cycle is 1,5-2 months long. 21-23 kg oyster mushroom can be picked from 100 kg substrate.

When cropping is over, the blocks are removed from the growing area and the rooms are cleaned and sterilized. The most commonly used hybrid strains (HK35, P80, Photios, Ikaros) can be cultivated throughout the entire year. Some of them tolerate higher of lower temperatures, so by the rotation of the different strains a whole year long cropping is ensured even in less modern growing facilities.

Test your knowledge!

- What are the differences between the dry and the wet heat treatments of the oyster substrate?

- What are the main steps of oyster cultivation?

- How is oyster mushroom picked?

- What kinds of substrate preparation methods are used?

- What are the optimal conditions for the spawn run of oyster mushroom?

References

Chang, S.T. (2000): The world mushroom industry: Trends and technological development. International Journal of Medicinal Mushrooms, 8: 297-314.

Győrfi, J., Geösel, A. (2008): Gondolatok a gombatermesztésről. Agrofórum, 19, 1: 36-38.

Hajdú, Cs. (2008): A termesztett Pleurotus ostreatus hibridek tulajdonságainak javítása és új hibridek előállítása vadon termő törzsek alkalmazásával. Doktori disszertáció.

Kovácsné Gyenes, M (2010): Laskagombafajok. In: Győrfi, J. (szerk): Gombabiológia, gombatermesztés. Mezőgazda Kiadó, Budapest.

Mushroom Growers Handbook 1. (2004). Oyster Mushroom Cultivation, Mushworld, Seoul.

Oei, P. (2003): Mushroom cultivation. Backhuys Publishers, Leiden, 1-429.

Royse, D. J. (2003): Cultivation of oyster mushrooms. The Pennsylvania State University, Pennsylvania, USA.

Somosné Nagy, A. (2010): Laskagomba fajtaspecifikus termesztéstechnológiájának fejlesztése. Doktori Értekezés, BCE, Budapest.

Szabó, I. (1986): A laskagomba termesztése. Mezőgazdasági Kiadó, Budapest.

Szili, I. (2008): Gombatermesztők könyve. Mezőgazda Kiadó, Budapest.

van Griensven, L.J.L.D. (1988): The Cultivation of Mushrooms. Mushroom Experimental Station, Horst.