Button mushroom (Agaricus bisporus) cultivation

Author: Anna Szabó

Commercially available compost

Depending on the mushroom growing house types, growers can either buy bagged or bulk composts. Those who produce on one level (mainly in cellars) usually buy polyethylene bags, each containing 15-20 kg of phase II. or III. compost. The size of the bag is usually 40 cm in diameter and 25-35 cm height. Some growers have special shelves in their mushroom houses, where they use bags to grow on multiple levels.

Compost can also be bought in blocks. Blocks are filled with 18-22 kg of phase II. or 16-18 kg of phase III. compost and have rectangular shape. They are put on the shelves of the mushroom houses next to each other, thus creating an almost steady surface. The size of one block is usually 50x35x17 cm.

Variable compost forms for different cultivation systems

For growing in Dutch-type houses, bulk compost is purchased. A special (air-conditioned) truck transports the bulk compost all the way into the growing area. A machine fills the compost directly from the trucks into the multiple level shelves.

Mushroom growing facilities

Button mushroom can be grown in different kinds of facilities as long as the ambient conditions can be regulated according to the developmental stage of the mushroom. The most important conditions that have to be controlled are temperature, humidity, fresh air and CO2 level. Unlike most other cultivated mushroom species, buttons do not require light during the growing period. On the contrary: white button mushrooms turn slightly brown, cream-coloured if grown in light, which not preferable by consumers.

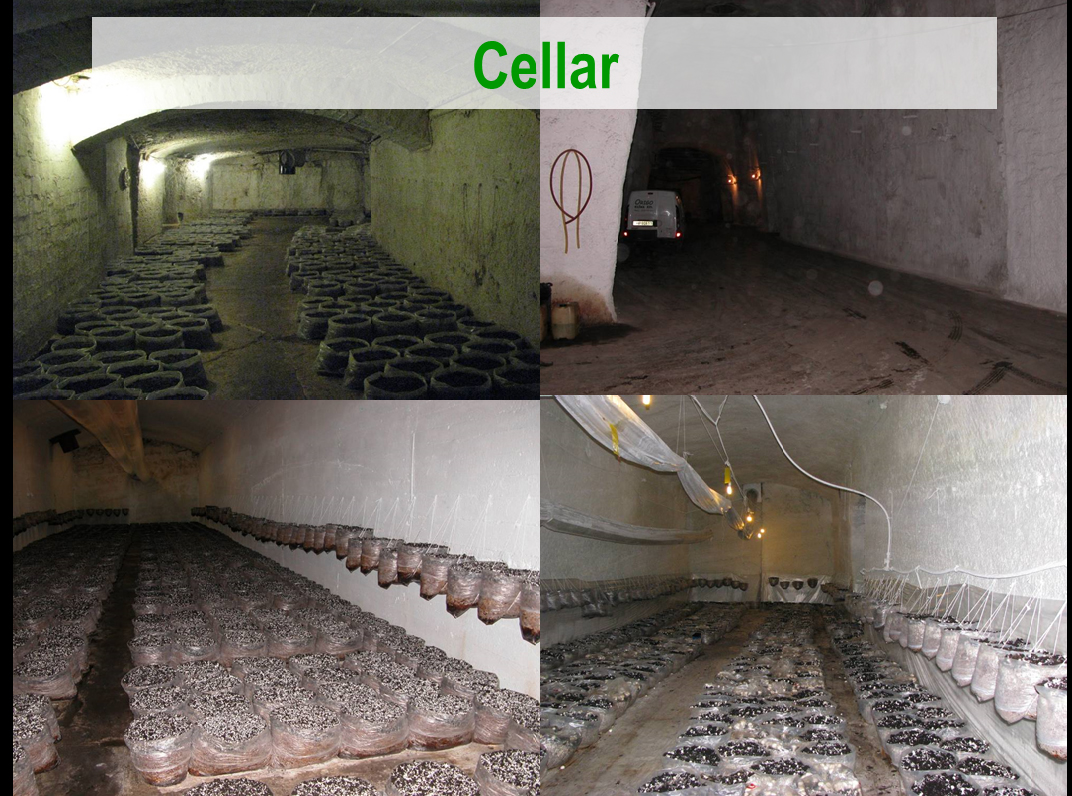

Limestone cellars

In Hungary, 45% of total button mushroom production is grown on polyethylene bags in limestone cellars. One advantage of cellars is if the slab is thick enough (around 10 m), the temperature does not fluctuate easily. Unfortunately, in most cases slab thickness is only 4 meters, thus the temperature depends more on the outside weather conditions.

Another important element is the height of the growing area. Sufficient chamber volume helps providing the required 25-27˚C compost temperature with lower costs. The most unfortunate disadvantage of cellars is the low utilization rate. Growing takes place on one level and it is hard to use the different machines for transportation and manipulation of materials and products. Air-conditioning systems and equipments of the small cellars are not as effective as in larger growing rooms, which impact not only production management and work organization, but the mushroom quality as well.

Although nowadays growers are required to provide the trader with the formerly agreed amount of product at a certain time, which is not easy in case of cellar production, but small scale growers (especially family enterprises) will continue to use this traditional method of growing.

Button mushroom growing in limestone cellars

The difficulties of cellar growing (in Hungarian)

Agricultural buildings

In the past decades, button mushroom cultivation has been started in many unused agricultural buildings (such as cowsheds, pig holdings and poultry houses) after proper insulation and air-conditioning system was installed.

Transportation and handling of materials are easier than in cellars. Also, cultivation can take place on multiple levels by using shelve systems.

Button mushroom growing in agricultural buildings

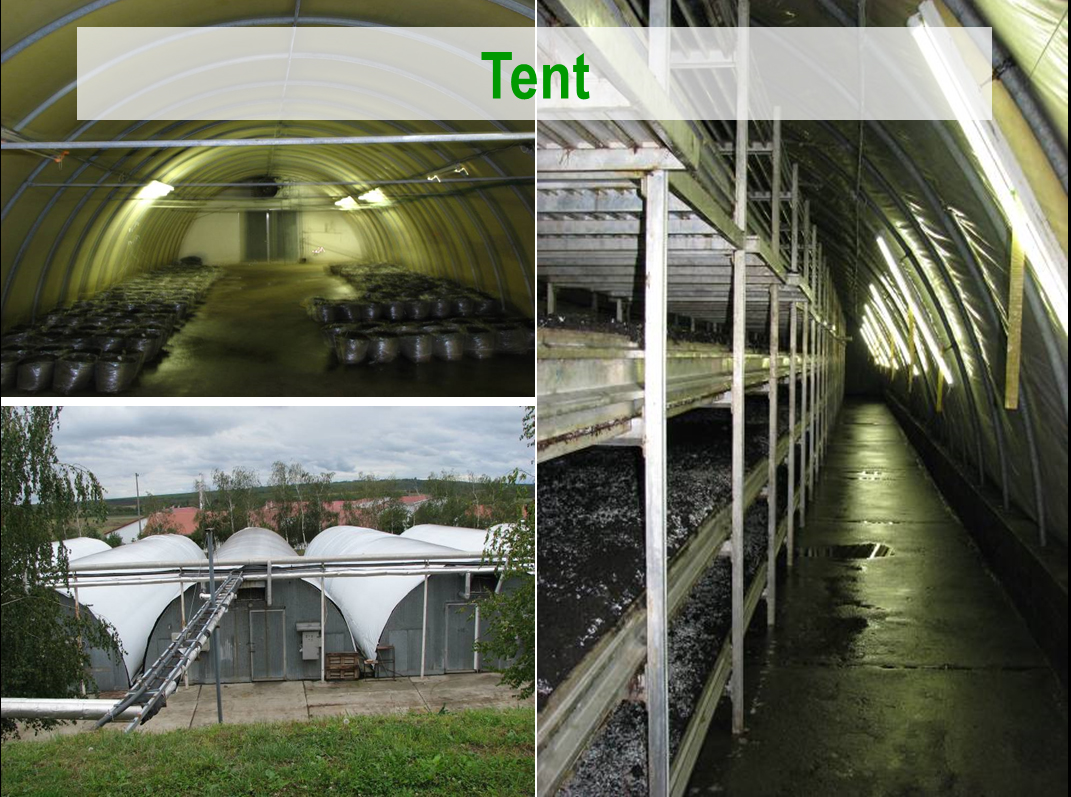

Mushroom houses or tents

Nowadays mushroom growing in tents is quite common. Usually blocked compost is used and placed on 2-3(-4) levels of special shelves. By proper air-conditioning, production is possible throughout the entire year. The trusses are steel tubes 4-5 m in radius. The tents are usually 40 m long (any longer would make air-conditioning difficult). The truss is covered by two layers of plastic with 10-20 cm thick glass wool in between. In order to minimize radiation, UV net is laid on the outside and black plastic covers the inside of the tent. Concrete flooring is easier to clean and aids effective transportation and handling.

Button mushroom growing in mushroom tents

Dutch-type mushroom houses

This type of buildings is the most modern facilities used for mushroom growing. Since construction costs are rather high, the most effective growing methods (using phase III. compost and highly automated air-conditioning, irrigation etc. systems) are preferable for economic reasons. With 6 rooms (plus packing and storing rooms and social facilities) continuous production can be realized. Each room has two shelf systems with 6 levels, respectively. The bottoms of the shelves are made of aluminum, the frame and the posts are steel. The structure and stability of the frame is especially important, since it is the guide of the machines and equipments used for irrigation, casing, picking etc. 134 cm wide, 18-27 high compost layers can be put on the shelves. The use-surface of one room can be as big as 518 m2 or more. Since one cropping cycle is approx. 6 weeks long, 8-8,5 cycles can be fitted into a year. Expanding the production area is done by adding more rooms to the facility.

Button mushroom growing in Dutch-type mushroom houses

Mushroom growing from the beginning

Mushroom growing on phase II. compost

Phase II. compost have to transported from the compost plant to the grower in a clean, preferably closed vehicle the shortest possible time. Overheating may occur during transportation in the summer, which damages the spawn. The risk of winter transportation is the opposite: the spawn and compost could freeze in the peripheral bags. Spawn run and cropping is influenced by the conditions of transportation.

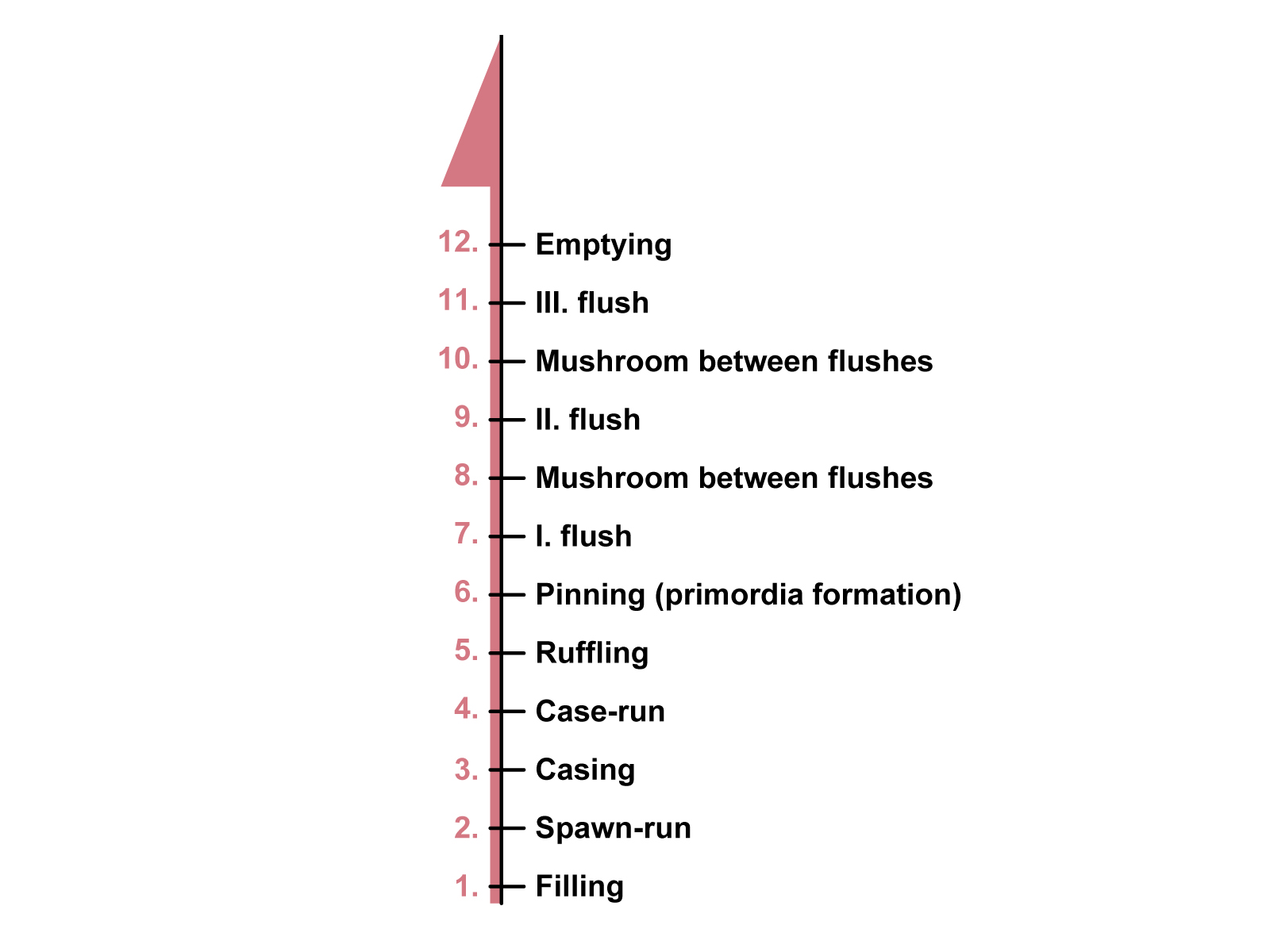

The steps of cropping in case of phase II. compost

Filling

(Since phase II. compost is not used in Dutch-type mushroom houses, only the cellar and tent growing is presented here.)

Before the bags or blocks are carried and put in, the growing room, growing area has to be cleaned and disinfected. The bags can be arranged various ways, depending on the size and type of the rooms. A “bed” is usually not wider than 120 cm, so the pickers could reach the bags from both sides of the bed. 60-70 cm is left between the beds in one level or between the shelves in multiple level growing (Fig 7). Season also influences how the beds and rows are formed. In winter the bags are put closer to each other, using their own heat to keep optimal temperature in the room, while in the summer space have to be left between the bags to prevent overheating. The blocs are usually placed next to each other on the shelves, thus creating a continuous surface.

Approximately 100 kg (around 5 bags or 4 blocs) compost is put on 1 m2 in one level growing. In shelf systems more bags or blocks fit on 1 m 2, this way the use-surface is bigger, cultivation is more effective and economic.

The weight of the bags are equalized, the bags are shaped (and if necessary compressed) in order to aid fast and uniform spawn run. By the end, each bags have to be the same height (35-40 cm in the winter and 28-30 cm in the summer), so casing will be homogenous and equal.

Beds of bags in cellar cultivation

Right after they get in the room the openings of the bags are folded, only a 5-6 cm rim is left (which will be later filled with casing). The bags (in beds) are then covered by plastic or paper, so the compost will not lose moisture, an optimal CO2 level can be provided for the mycelia to grow and the compost is protected against pests. Both plastic and paper covers can only used once, in one growing cycle for sanitary reasons. The blocs are opened after they are put on the shelves. One side of the plastic cover is cut off (only a 5-6 cm rim is left).

During filling, the room temperature should be between 18 and 20˚C in the summer and 22-24˚C in the winter, while the compost temperature (core temperature in the middle of the bags and blocks) is 25-27˚C.

Spawn run

The optimal temperature for most button mushroom strains is 25-27˚C during spawn run. Higher temperature (above 30˚C) damages or even kills the mycelia. Lower than optimal temperature result is uneven spawn run and yield loss, or in case of extremely low temperature (below 20˚C) mycelial damage. Both room and compost temperature has to monitored and registered continuously together with humidity, which is optimal between 95-100% during spawn run. In order to prevent water loss in the compost, the passages and covers are irrigated and humidifiers are used. The optimal CO2 level is around 5000-6000 ppm.

3-4 days after the bags are placed in the rooms, the compost around the spawn starts to turn white/light grey, which shows that the mycelia started to grow into the compost from the grain (spawn). The duration of spawn run depends on the quality of the compost, the amount of spawn used and the temperature and other ambient conditions. Spawn run is usually finished in 14-16 days.

When the mycelia completely colonized the substrate (the spawn run is finished), the compost is considered to be phase III. compost. The next step is casing. From this point, with minor exceptions, the growing process is the same in all types of facilities, in cellars, mushroom tents and in Dutch-type houses as well.

Casing

When the spawn run is finished (phase III. compost), casing soil is applied on the surface of the bags, blocks or the bulk compost. Without casing button mushrooms do not form fruitbodies (or only a few), since casing:

- is the water source for the growing fruitbodies;

- prevents drying of the compost;

- helps keeping humidity in the growing room;

- prevents CO2 to escape the compost, which is important for mycelial growth;

- provides low osmotic pressure;

- acts as a buffer between the compost and the air, which is important especially in case of sudden temperature changes;

- protects the compost against pests and diseases.

In Europe casing soil consists of 80-90% peat moss and 10-20% industrial lime from sugar refinery.

A high quality casing material has good water absorption and retaining capacity, low nutrient and sodium content and low conductivity. Casing soil contains bacteria, most importantly Pseudomonas putida, which promotes mycelium run in the casing and affects the forming of fruitbodies. If the casing soil is sterilized, a commercial bacteria solution (containing P. putida) has to be added.

One of the most important roles of casing soil is that (unlike the compost) it can be irrigated and it is the water source of the developing mushrooms. If the quality is good, the casing will not lose structure because of continuous irrigation during cropping. Low quality casing becomes dense with time and loses the optimal air-moisture rate. The 7-7,5 pH is good for the button mushroom, but not preferred by competitive fungi species that grow better in a slightly acidic substrate.

Casing soils have to be free of pests and pathogens. That is why some growers disinfect the material with formaldehyde.

Casing by hand in cellar cultivation (before-after)

The colonized compost is covered with 4-6 cm casing. To achieve uniform cropping, the casing layer has to be equal on each bag. If the surface is flat, the fruitbodies are more likely to appear at the same time (which is preferable when the mushroom is picked by machine). Uneven surface result in longer flush (the mushrooms do not grow together and can be picked for a longer period), which is good for handpicking.

For prevention, “plant” protection products can be added to the first irrigation following casing. Sporgon 50 WP (3 g/m2) against pathogens, Dimilin 25 WP (4 g/m2) against mushroom fly larvae or Nemacel and Nemasys-M (biological insecticides) can be used in Hungary.

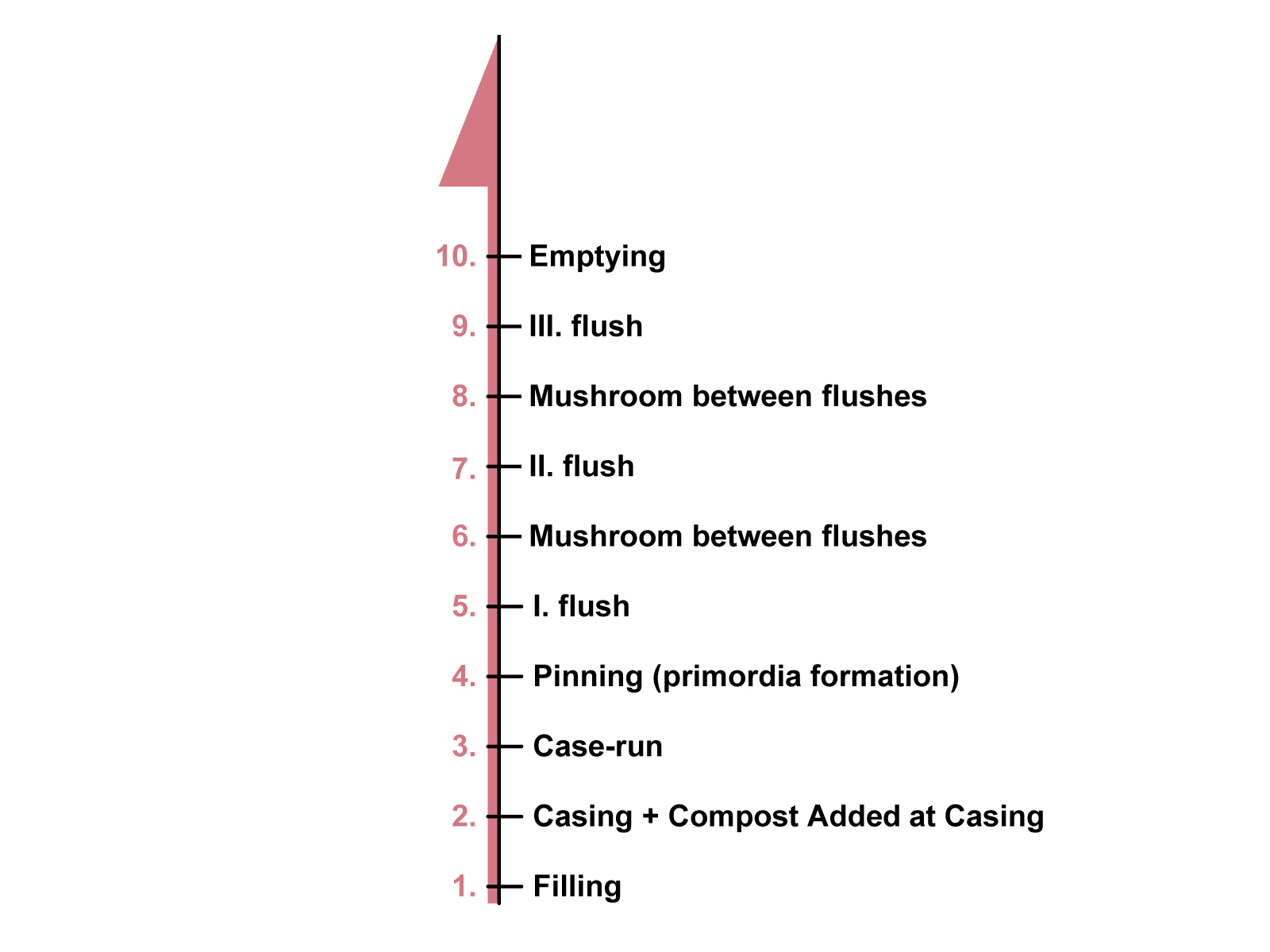

The steps of cropping in case of phase III. compost

CAC-ing

CAC-ing means “Compost Added at Casing” and is done by mixing colonized (phase III.) compost or casing inoculum into the casing soil. By using CAC-ing there is no need for ruffling, which shortens the time between casing and cropping (the first flush appears usually 2-5 days earlier), and manual work can be speared in cellars and tents. Shorter schedules enable more cultivation cycles per year. CAC-ing also gives a higher yield.

Another reason for using CAC-ing is that growers are increasingly using heavier casing soil. This results in less mushrooms, but a higher individual piece weight. Heavy casing soils can however often have highly compacted structures. Adding mycelium lightens the casing soil structure, and creates more constant evaporation.

Another reason for cac-ing is the development of stronger mycelium - if the watering schedule is adapted. If less but stronger mycelium develops, there will be fewer pinheads - but they will grow into better quality mushrooms.

Casing spawn can be bought from spawn manufactures. It is a material with similar characteristics to casing soil and colonized by mycelia (the same strain that the compost contains). Mixing 30 l/100-150 m2 casing spawn in the casing soil speeds up colonization and the first mushrooms can be picked on the 16-18th day.

‘CAC-ing inoculum’ can also be used. This is a type of spawn with the added advantage of being pure and pathogen-free. Inoculum is also easy to weigh and mix in with the casing soil.

Many growers spare the cost of casing spawn and use phase III. compost. The advantage of this solution is the risk that it could contain competitors (especially Trichoderma species). If the compost is infested, but no symptoms are visible yet, the grower could easily spread the disease himself during CAC-ing.

During spawn run is the casing (= case-run), its temperature has to be at least 22˚C, the compost 25˚C and 95-100% humidity is optimal (Fig 10).

The surface of a bag following CAC-ing (the colonized compost is visible in the casing soil)

Mushroom farm visit in Warwick

Incubation

The process of the colonization of the casing soil by mycelia (from the compost, from compost or casing spawn added at casing) is called incubation. This is a very sensitive part of the cropping cycle and irrigation has to be done by special care because of the growing mycelia. The mycelial growth affects the yield as well as the quality of the mushrooms. Intensive irrigation (2-3 l/m2) is started 3-4 days after casing.

In a few days the mycelia grows into the casing soil from the compost. When the mycelium is mature enough and the ambient conditions are changed to promote fruitbody forming, primordia (pinheads) appear on the surface of the casing. In the nature button mushrooms grow in groups (several fruitbodies grow from the “same base”) not individually, which is not favorable is growing, because the mushrooms are squeezed together and the caps deform (and become less attractive to the consumer). Moreover picking is difficult, since the mushrooms in the group are not the same size and not picked at the same time. If the picker is not careful enough, by removing the biggest mushrooms, they can easily damage the smaller ones, which will than go to waste. To prevent fruitbody forming in groups, the casing soil is ruffled on the 6-9th day after casing (when two thirds of the casing layer is colonized by the mycelia), which causes the mycelia to “break” and results in individual frutibody forming, uniform size and distinctive flushes. Naturally, with CAC-ing ruffling is not necessary.

Ruffling is done manually in cellars and tents. The casing is piled in the middle of the bag, then mixed and turned carefully and spread again on the surface of the compost. Ruffling is mechanized in Dutch-type houses, although in most cases in can be spared by CAC-ing

If a second fungicide treatment is necessary, it has to be done at the last irrigation before ruffling. Irrigation has to be suspended from the day before ruffling until 2-3 days after it, to let the mycelia regenerate.

At ruffling, the compost temperature is 25-27°C, relative humidity is 95% and the CO2 level is 5000-6000 ppm. More fresh air is necessary from the 8-11th day after casing. Pinheads (primordia – initial fruitbodies) appear 3-6 days later and can be picked 3-6 days after.

Button mushroom cultivation at the DOFE Ltd. (Dunavarsány, Hungary)

Cropping

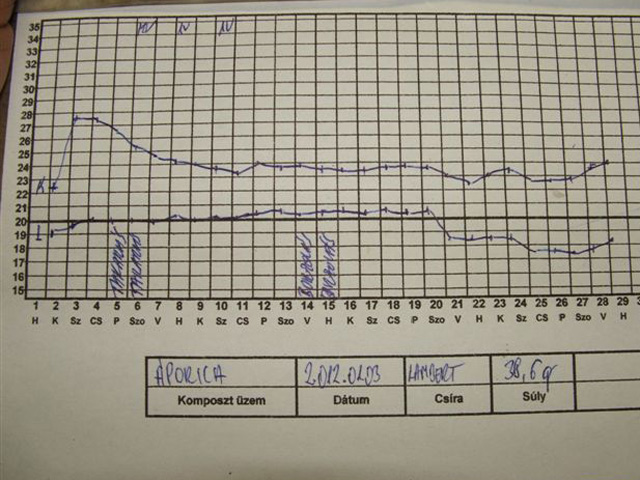

Ambient conditions are modified after ruffling. The compost temperature is lowered (by adding fresh air), until it reaches 18-20°C. The CO2 level is also reduced (from 5000-6000 to 1200-1800 ppm). Relative humidity is adjusted to 92% from the initial 95%. Changing these three conditions together promote fruitbody forming: it forces the vegetative mycelia to step into the generative phase and produce primordia. Monitoring and registering the ambient conditions aid preventing errors during cropping. This can either be done manually on paper or automated by a computer.

Mushroom cultivation notice with compost- and air temperature and technological steps

If growers would like to pick bigger (but less) mushrooms in the first flush, they lower the temperature (and humidity and CO2 level) in 4 days. If they prefer more, but smaller mushrooms, the cooling has to be shorter by 2 days. Pinheads appear 11-13 days after casing. The stem and cap are still not be distinguished in next developmental stage (peahead). Only in the button phase can the stem and the cap told apart. Fruitbodies should not be watered until they pass pinhead phase. The amount of water added in this stage influences yield. From the number of pinheads the probable yield can be estimated, which is important, since the water added on each m2 has to be the same amount as the yield expected in kg. The airflow should be adjusted, so the surface of the mushrooms could dry quickly to prevent fungal diseases. Fruitbodies should not be irrigated from 2 days before picking.

Cropping

The lengths of the cropping period depend on the temperature, the cultivated species, the quality of the materials (especially the compost, casing soil and spawn) and the purpose of production (e.g. fresh or canned mushroom). In order to ensure gas exchange and evaporation, the temperature has to be different in the compost (20°C) and in the room (18°C). 600-1800 ppm (0,06-0,18%) CO2 is optimal during cropping, which can be adjusted by intensifying air-flow. Relative humidity has to be 90-92% during cropping. Low humidity accompanied by intense air-flow could lead to the drying of the mycelia. Moreover the surface of the fruitbodies could dry and flake and the mushrooms themselves lose weight. Too high humidity (above 95%) inhibits evaporation, which cause the mycelia to stay in vegetative state and continue growing on the surface of the casing instead of forming fruitbodies.

Flushes

Fruitbodies of most cultivated species (like button mushrooms) appear in flushes during cropping. It means that the fruitbodies develop and mature together and they can be picked at the same time (mushrooms are usually picked not it biological but economical maturity). One flush is around 4-5 days long – mushrooms are picked during this time. Then for 5-6 days (before the second flush) only a few fruitbodies can be picked, they are able to grow to very big (‘grilled-mushroom’ size). The third flush starts 8-9 days later. The first flush gives the highest quality and 40-45% of the total yield. Another 41-45% is picked in the second flush, while only 5-10% in the third. Growers usually start a new cycle when the third flush is finished, since neither the quality nor the quantity is sufficient after that.

In Hungary the base of the button mushroom’s stem (covered with casing soil particulates) is removed during picking. The mushrooms are put in boxes of different sizes. The fruitbodies are clean, free of any stains, casing soil and discoloration. The categories of button mushrooms are based on their cap size. In Europe the 2-4 cm buttons are preferred, while Hungarian consumers like the bigger size (5-6 cm). Another category is the fully matured button mushroom with opened gills (Jump to chapter 13; EU standards for mushroom).

Intermediate flush

Some growers prefer picking mushrooms between the flushes too (intermediate flushes), especially in Hungary, where bigger buttons are preferred. Letting fruitbodies to grow between flushes means extra yield, but it also delays the forming of the next flush and elongates it. When the first flush is over, the compost temperature lowers, which sets back mycelial regeneration. To aid mycelial growth the room temperature is adjusted a bit higher.

Picking

Button mushrooms are mostly picked not it biological but economical maturity, when the cap is still closed and the quills are not seen. Depending on the demand of the consumers, buttons are usually packed in paper or plastic boxes (holding 0,25 to 1 kg mushroom). Picking has to be done with special care. What makes it difficult is that the fruitbodies are not the same size and cannot be picked at once. The mushrooms have to be picked carefully, so no damage is caused to those left on the surface for further maturing.

The picker holds the mushroom in one hand, while cutting the base of the stem with a knife in the other hand. The quality of the knife is very important. Pickers use special knives with curved blades and pointy end. The mushrooms should only be touched with fingertips, since any pressure or touch causes discoloration on the clean white surface of the mushrooms. Each mushroom is touched – but only once (picked, stem cut and placed into a box with one hand). An average of 15-20 kg mushroom is picked by one person in an hour in a cellar, while almost 50% higher in a Dutch-type house.

Button mushroom picking

While picking the mushrooms, the workers check all bags and shelves looking for signs of infestation or pests. The daily work always starts in rooms with first flush; from here the workers go to second and third flushes to pick. This way the risk of spreading diseases in minimized. In Hungary 32-34(-36) kg button mushroom can be picked from 100 kg phase III. compost but it is also possible to pick 40-45 kg in several crop.

Crop termination

Spent or used compost is the material that is left after cropping. In consists of compost, casing soil and mycelia of the cultivated species. When removing it from the growing area, the grower has to be careful and minimize the possibility of spreading diseases. After the spent material is taken out, the floors of the cellars are swept or washed then sterilized together with the shelves and equipment.

In Dutch-type houses the rooms are closed and cooked or steamed out together with the spent substrate, so the compost is not removed before the cleaning process starts. The vents are closed and thermometers are placed in the compost to make sure that the whole material reaches 70°C (for 12 hours). Naturally the cost of this process is high, but the damage deriving from inefficient sanitation is even higher. After steaming the material, it is removed from the growing area. Then the surfaces, shelves and walls are washed. Metal and concrete surfaces are easier to clean.

If post-crop handling is not done carefully, spores and mycelia of pathogenic fungi, bacteria or eggs or larvae of pests could survive in cracks and corners of the room or on the surface of the shelves and equipment and could infest the next cycle.Only after complete cleaning and disinfecting can the next cycle start.

Test your knowledge!

- What are the steps of growing in case of phase II. compost?

- What are the advantages and disadvantages of cellar cultivation?

- What is a Dutch-type mushroom house?

- What is ruffling?

- Why do we use casing in button mushroom cultivation?

- What ambient conditions are adjusted to promote fruitbody forming?

- What is intermediate flush?

References

Eger, G. (1972): Experiments and comments on the action of bacteria on sporophore initiation in Agaricus bisporus. Mushroom Science, 8: 719-725.

Fermor, T.R., Wood, D.A. (1981): Degradation of bacteria by Agaricus bisporus and other fungi. Journal of General Microbiology, 126: 377-387.

Győrfi, J. (2003): Csiperketermesztés nemcsak vállalkozóknak. Szaktudás Kiadó Ház, Budapest, 5-199.

Győrfi, J. (2010): A csiperkegomba (Agaricus bisporus) termesztése. (In: Győrfi, J. (szerk): Gombabiológia, gombatermesztés. Mezőgazda Kiadó, Budapest, 139-187.

Long, P.E., Jacobs, L. (1968): Some abservation on CO2 and sporophore initiation in the cultivated mushroom. Mushroom Science, 7:, 373-384.

San Antonio, J.P., Thomas, R.L.K. (1972): Carbon dioxyde stimulation of hyphal growth of the cultivated mushroom Agaricus bisporus (Lge) Sing. Mushroom Science, 8:, 623-629.

Stanek, M. (1974): Bacteria associated with mushroom mycelium (Agaricus bisporus (Lang.) Sing.) in hyphosphere. Mushroom Science, 9, 1: 197-207.

Szili, I. (2008): Gombatermesztők könyve. Mezőgazda Kiadó, Budapest.

van Griensven, L.J.L.D. (1988): The Cultivation of Mushrooms. Mushroom Experimental Station, Horst.