Preparation of compost and uses of spent mushroom compost

Author: Anna Szabó

Cultivation of button mushrooms (Agaricus bisporus) started in France, in the 17th century. The royal gardeners were the first to notice that mushrooms grow in the hotbeds which are “heated” by wheat straw-horse manure compost. This elementary (and since then superseded) technology spread firstly in France (the abandoned tunnels of quarries in Paris), than in Europe and the whole World. From all the cultivated mushrooms buttons have the most developed and detailed cultivation technology, and they are cultivated in the largest scale. Unlike most mushroom species, button mushrooms form only two basidiospores on their basidia (e.g. other Agaricus species have four).

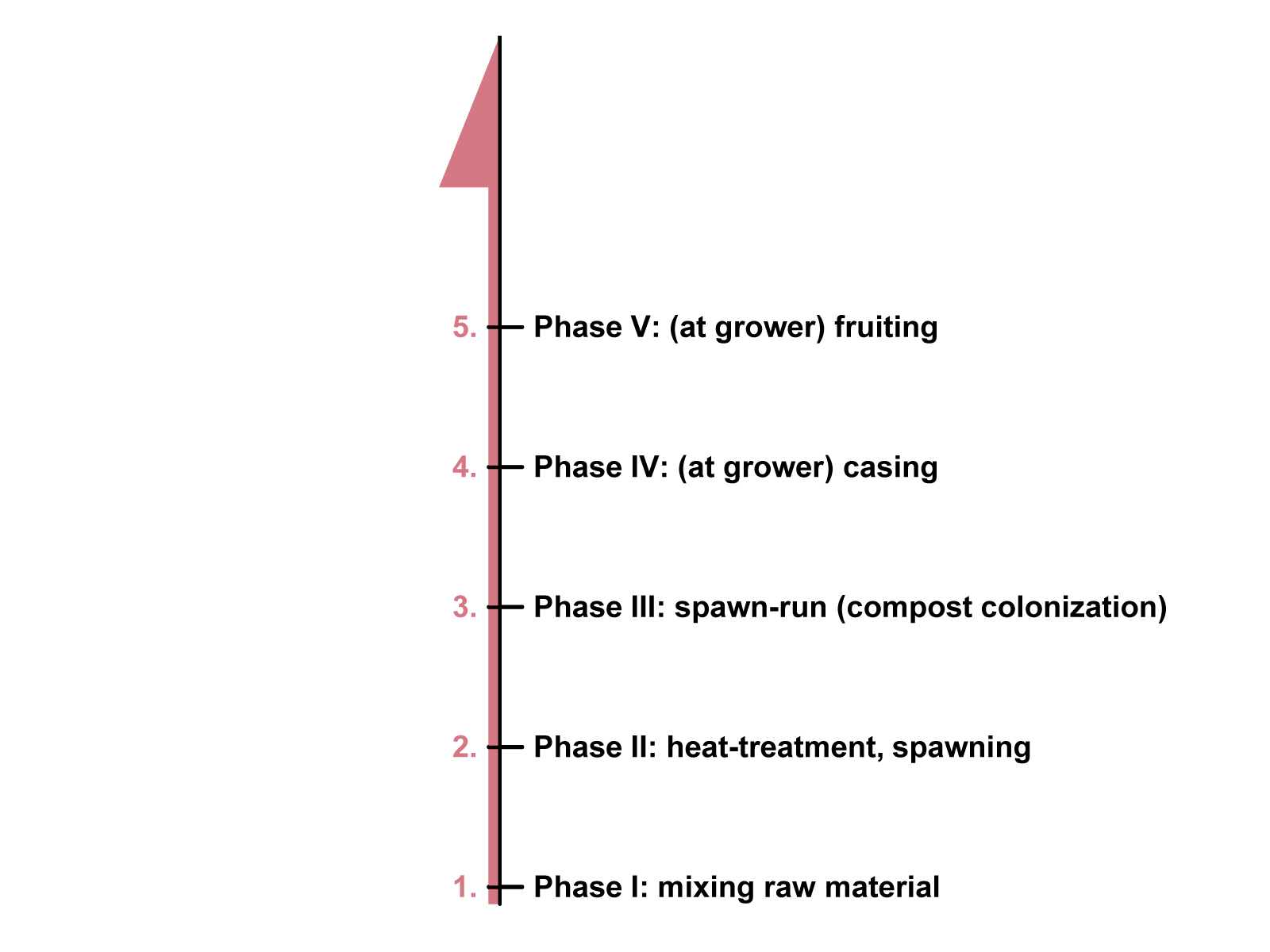

Steps of button mushroom cultivation

The development of button mushrooms and other mushroom species which form fruitbodies, consists of two stages: 1. vegetative growth (mycelia development) and 2. generative growth (forming of fruitbodies). These naturally occurring sequences are present during cultivation as well: the mycelia on the spawn first colonizes the compost, than following casing (and temperature and CO2 level changes) it finishes vegetative growth and starts forming fruitbodies (generative growth).

In modern mushroom cultivation the next steps/phases follow each other:

- Phase I.: mixing of the ingredients (straw, chicken and horse manure, water and gypsum) and starting aerobic fermentation.

- Phase II.: (tunnel composting): in modern compost plants finishing the compost takes place in insulated tunnels. By the end of the process, following spawning the compost is ready for button mushroom cultivation, as it is an adequate nutrient source for the mushroom, it is suited for the growth of button mushroom to the exclusion of other fungi and bacteria, it is free of pests and pathogens and no longer contains harmful amount of ammonia. Phase II. compost is spawned but not yet colonized by the mycelia. This type of compost can either be sold to growers (who will then wait for spawn run) or it can be moved into a spawn run tunnel, where the conditions are ideal for mycelia growth and the whole Phase II. compost pile will be colonized in 14-16 days.

- Phase III. compost: a compost already colonized by the mycelia and ready for casing. The costs of the approx. 2 week period (while following spawn run Phase II. compost turns into Phase III.) considerably increase the value, thus the price of Phase III. compost is higher. In spite of the higher price, growers prefer Phase III. compost, as instead of waiting for the 2 weeks period of spawn run, they can immediately start casing and growing (and can have more production cycles a year). Besides, some growers do not have the most modern production systems and technologies and it is sometimes difficult to them to ensure ideal conditions (temperature, humidity and adequate amount of fresh air) for spawn run. In Hungary, only 10% of the total compost amount was sold in II. phase in 2011, the other 90% was Phase III. compost.

- Phase IV. compost: Phase III. compost is cased and the spawn is allowed to colonize the casing layer before the compost is sold to growers and delivered to the growing units. Even pins/pinheads (pinhead: the first developmental stage, initials of a fruitbody, when the cap and stem cannot be distinguished) or more mature little mushrooms are visible on the surface of the casing. Phase IV. compost is produced mainly in Holland, Germany and Belgium.

- Phase V.: cropping. The fruitbody initials grow until they reach a harvestable size. 18 to 20 days after casing normal (3-5 cm cap diameter) sized button mushrooms can be picked for 3-5 days (1st flush). Button mushrooms grow in flushes: picking periods are followed by a few days, when no mushrooms can be picked, than this cycle repeats as long as the compost contains enough nutrients for the mushrooms to grow. In Hungary usually 2-3(-4) flushes are picked in one growing cycle. Waiting for more flushes is not economic, as by each flush the quantity and quality of the mushrooms decrease, and at the same time the amount of pathogens and pests increases.

Preparation of compost

Button mushrooms are heterotroph life forms (they use carbon sources prepared by photosynthesizing plants). Button mushrooms are grown on compost, which is an adequate nutrient source for the mushroom; it is homogenous but not sterile (!). Two of the main ingredients have always been straw and horse manure since button mushroom cultivation started. Horse breeding decreased throughout the centuries and nowadays it is available in a much lower amount than before, but is it still used for compost preparation. Button mushroom needs water, carbon source, nitrogen source, minerals and vitamins to grow.

Ingredients of the mushrooms compost

In Hungary wheat straw (and sometimes corn stem), chicken and horse manure, gypsum, water and supplements with high nitrogen content are the main ingredients of the button mushroom compost. Vitamin sources are the raw materials themselves and those microorganisms, which get into the compost during the production process.

Straw of wheat and other grains

Straw serves as a carbon source, since it contains cellulose and hemicellulose. The quality and quantity of the straw determines the water absorbing and retaining capacity of the compost. While in Europe wheat straw is used almost exquisitely, in other countries corn cob, hay, grass and other plant parts are also used for compost preparation.

Straw bale waiting for composting

In each country, the main carbon source in the mushroom compost is that straw (or another part of the plant), which is available in the biggest amount. With its structure and availability in both quantity and price, wheat straw is an optimal compost ingredient. Paddy straw has almost the same characteristics as wheat straw. Barley and oat can be used to, but their thinner and softer straw (although absorbs water more quickly) lose structure earlier. The quality of the whet straw is influenced by many things: the weather conditions the growing period, the variety and the use of fertilizers, fungicides and insecticides. Although plant protection products degrade during composting, but in some cases they were detectable even in the mushrooms themselves, which were grown on their compost. Wheat straw should be stored for a few months to weaken the wax layer on the straws, which interfere with water absorption during the composting process.

Horse manure

Wheat straw based horse manure was used for mushroom growing from the 17th to the 20th century. It was the most convenient and the cheapest material for this purpose. The quality of the horse manure is highly variable. It consists of the urine and waste of the horse mixed with some straw. The quality is influenced by the type and quantity of feeding and straw and by the storage time and circumstances of the manure. It is very important not to use horse manure that is stored longer than a week.

Chicken manure

Chicken manure is the nitrogen source in the compost, as it consists of 3,5-4% nitrogen, 30-40% water and 12-14% ash. Carbamide, ammonium nitrate and other materials with high protein content can be used as well. Sawdust and chips are used for bedding, thus the manure of broiler chickens is relatively dry and can be homogenized and mixed easily into the compost. Broiler chicken manure has quite balanced quality and is available regularly.

Gypsum

Gypsum (CaSO4) was used for balancing pH, but nowadays is important for its positive effect on compost structure.

Water

Water is essential for the mushrooms, since their fruitbodies contain 88-91% water. During the composting process, water is absorbed by the straw, so the aerobic fermentation (composting) commences as a result of the growth and reproduction of microorganisms, which occur naturally in the ingredients.

Wetting the wheat straw

Each kilograms of mushroom requires 2 liters of water, 1 of which is responsible for nutrient transport and one is needed for evaporation.

Preparation of compost

Mushroom compost develops as the chemical nature of the raw ingredients is converted by the activity of microorganisms, heat and some heat-releasing chemical reactions. These events result is a food source most suited for the growth of the mushroom to the exclusion of other fungi and bacteria. By the end of the process, the nutrients of the raw materials (wheat straw, horse manure etc.) convert into forms available for the mushroom. Compost preparation takes place in special, mostly automated compost plants. Although composting methods can differ in each plant, the basic theory and ingredient are the same.

Phase I.

Composting is initiated by mixing and wetting the ingredients. Usually the wheat straw and manure are together put through a compost turner while being watered. Then supplement and gypsum are spread all over the pile and put through the turner again. Piles are made, which are than regularly turned. The piles are 1,6-1,8 m high and as long as it convenient for the size of the plant and the capacity of the machines, workers and space.

Compost pile in Holland

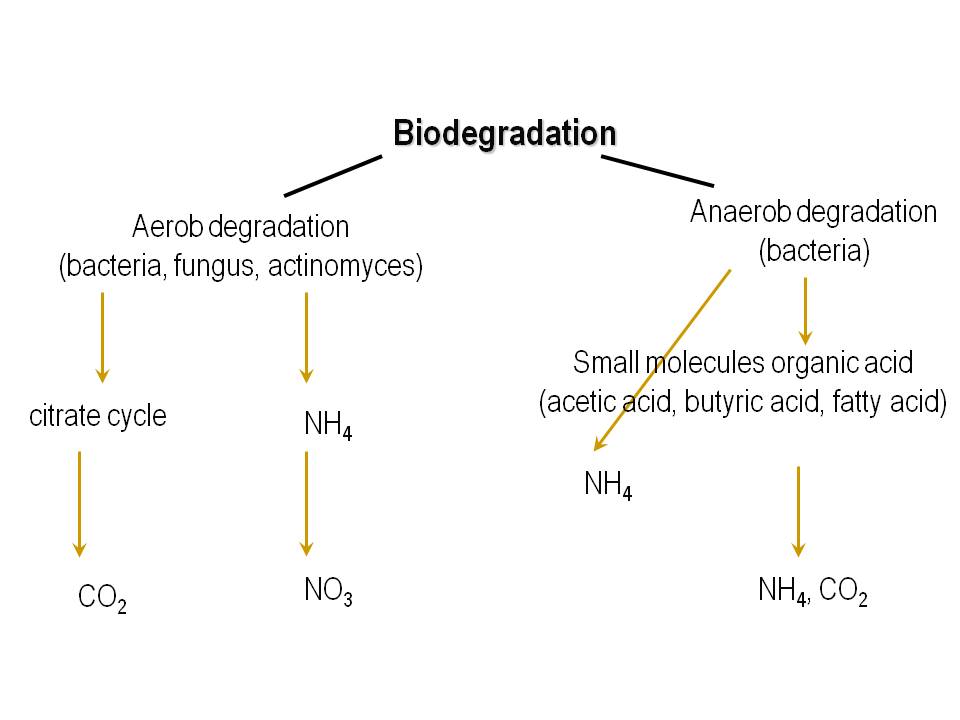

In the wet mixture, the number of bacteria and microscopic fungi grow and they start to degrade the raw materials. Some microbes degrade carbohydrates, while others hydrolyze cellulose, which produce carbon dioxide. For example, among many others the following microbe types are present during the composting process:

- Ammonifying bacteria: they produce ammonium by breaking down organic nitrogen compounds under aerobic or anaerobic circumstances.

- Nitrifying bacteria: they convert most of the ammonia into nitrites than nitrates, which is later assimilated by the mushroom.

- Denitrifying bacteria: they reduce some of the nitrate into nitrite than elemental nitrogen.

The microbe activity results a rise in temperature and the wax coating of the straw starts to degrade, the straw softens and start to absorb water. Usually 5-5,5 tons of water is added to 1 ton of mixture to reach the optimal water content by the end of phase I.

The temperature is around 20 ˚C at the beginning, but start to rise as soon as microbe activity and degradation of raw materials increase. It takes 2-3 days for the pile to heat up to the desired 78-80 ˚C. The temperature is monitored carefully in many points (inside and on the surface too) of the pile. Since the temperature varies in the different parts of the pile, it is needed to be mixed and turned regularly (usually on the 3rd, 5 th, 6th and 7th days). Turning is also necessary to avoid anaerobic conditions and to help equal watering. Too much turning has a negative effect on the compost structure.

Turning and mixing of the compost

Phase I. takes 10-14 days to complete, depending on weather conditions and the quality of raw materials. During the first phase of composting, the wet pile of ingredient has a very strong, unpleasant odour, for which sulphur compounds (e.g. dimethyl sulfide and hydrogen sulfide) are responsible. These compounds are highly pollutant and should be neutralized before they get into the air. The first phase normally is not indoor, but in Holland (because of strict environmental regulations) an indoor technology had to be developed.

Phase I compost filling into tunnel

Three versions of phase I. composting are common:

Outdoor composting: Traditional method, where the ingredients are mixed and wetted outside in piles.

Semi-indoor composting: The wetted and mixed ingredients are not put in piles outside, but placed on concrete floor or in long, 5,5 m high, 6 m wide opened tunnels or bunkers and force aerated through nozzles or spigots (little holes, perforations) in the floor. The holes are 25-40 cm far from each other. The temperature is constantly monitored through thermometers (around 6-8 in each tunnel); the system is almost fully automated. The compost pile is around 5-6 m wide and 3-4 m high. It has to be placed loosely on the floor to avoid anaerobic areas. Air is forced through the pile with high (5000-6000 Pa) pressure. Temperature starts rising and reaches 75-80 ˚C in 24 hours, which is than kept for 3 days. The whole pile is then moved into another tunnel or bunker, where the whole three day procedure is repeated. This is the last stage of the first phase.

It is now a common method and used in most compost plants (in Hungary as well).

Indoor composting: The compost is treated just like in case of the semi-indoor version, only the tunnels and bunkers are completely closed, so no unfiltered air or gas could escape.

Semi-indoor bunker and indoor tunnel composting

The timing and quality of semi-indoor or indoor composting is not as easily influenced by weather conditions as it is of outdoor composting. Another advantage is that harmful gases can be ran through filters, so pollution and odours can be reduced. At the end of phase I. the water content of the compost is 70-76%, the total nitrogen content is 2,2-2,6%, the pH is 7,2-7,4 and the C-N ratio is 18-20 to 1. The compost has a chocolate brown colour and a strong smell of ammonia.

Phase II.

One of the most important purposes of phase II. composting is pasteurization, which is necessary to kill any of insects (eggs, larvae or adults), nematodes, fungi (mycelia or spores), or other pests, that are present is the compost after phase I. The other purpose is to condition the compost and to remove the ammonia that formed during phase I. composting. Furthermore, homogeneity of the phase I. compost is never perfect, parts are always found that have lower temperature and contain pests and pathogens. During phase II. composting, the temperature of the entire pile gets equalized.

Filling of the tunnels by conveyer belt

The most modern way of phase II. composting takes place in special insulated tunnels with perforated floors, where the bulk compost is filled with special care for density and compression (it should allow gas exchange, since ammonia and CO2 will be replaced by outside air). These tunnels can completely tolerate high temperatures and low pH (ammonia). Before bulk composting became common, compost used to be filled in boxes, wooden trays of beds, the trays or boxes were stacked on each other and moved into special, environmentally controlled phase II. rooms. The advantage of bulk composting compared to the traditional ways is that it takes place in the composting plant and not in the production area, thus it does not take up place from growing.

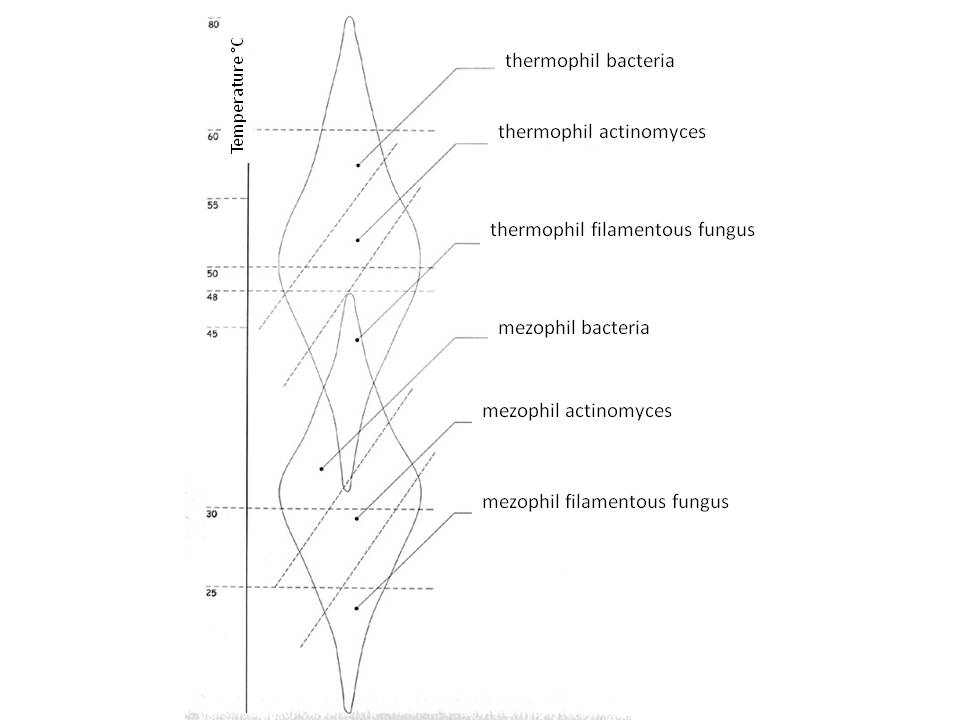

Phase II. composting is a controlled, temperature-dependent, ecological process using air to maintain the compost in a temperature range best suited for microorganisms to grow and reproduce. The growth of these thermophilic organisms (thermophilic= high temperature or even heat is needed for the organism) depends on the availability of carbohydrates and nitrogen (activity of the different microbes are shown on Fig 8.). These microbes are important, as they produce nutrients (or serve as nutrients themselves) in the compost, which are favorable for mushrooms but for other organisms not.

Activity of living organism during composting, depending on temperature

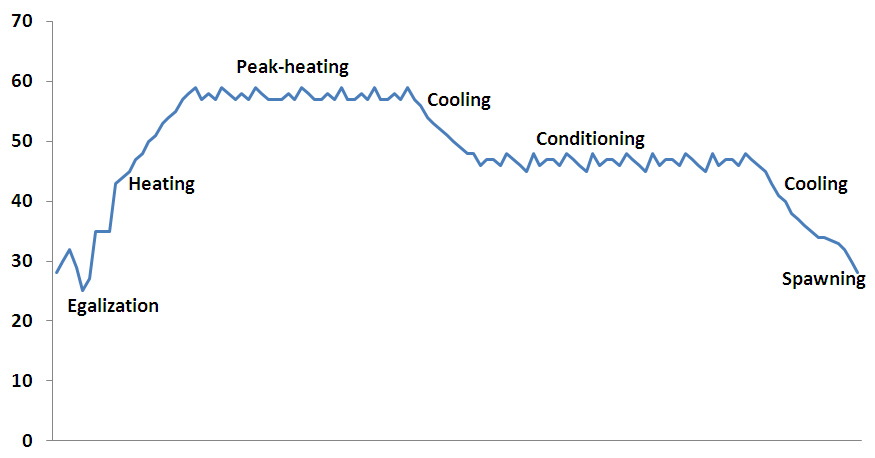

In case of tunnel composting, for the pasteurization to be the most effective the compost goes through a series of processes and stages while the following temperature changes and time periods are kept in the tunnels:

1. Filling: With special care for density and compression, phase I. compost is filled into the insulated tunnels with perforated floors.

2. Equalization: The temperature of the phase I. compost pile is equalized.

3. Heating (to peak heat): The compost is heated to 57-59˚C in 8-12 hours (1-1,5˚C/hour). This temperature is called the peak heat. The temperature will not get higher than this, since during the composting process the materials are not sterilized, only pasteurized, which means a lower temperature level.

4. Peak heat: The compost temperature is kept on 57-59˚C for 6-12 hours.

5. Slow cooling: The compost is cooled to 46-49˚C in 6-8 hours (1-1,5˚C/hour).

6. Conditioning: It lasts for 3-5 days, during which the temperature is 46-49˚C.

7. Cooling for spawning: The compost has to be cooled under 30˚C before spawn is added, as higher temperature would harm (or even destroy) the mycelia. It takes 14-24 hours to cool the compost from 46-49˚C below 30˚C.

Theoretical steps of compost heat-treatment

When pasteurization is finished, phase II. compost is transferred out of the tunnels. During this process, spawn is being added and mixed into the finished compost. Spawn is steam-sterilized grain colonized by the mycelium of the mushroom and is used to “seed” the compost. Grains are initial points of mycelium growth (see chapter 5 – LINK 5. fejezet). Usually 0,8-1,4 liters of spawn is added to 100 kg compost. Spawn is distributed on the compost and mixed by a special spawning machine with tines or small finger-like devices along the conveyer belt, on which compost is being moved out the tunnels. In addition, the grains themselves become supplemental nutrient.

Another method it when instead of mycelia covered grain (traditional spawn) is used for spawning, but phase III. compost. Since phase III. compost is already colonized, it acts like a normal spawn and served as the source of mycelia, just like the grain. This special type is called phase II½. compost. It was prepared in Hungary as well, but nowadays is not common anymore.

Adding supplements to the compost with the spawn increases the yield (by 3-10 kg/m2). Supplements have high protein and/or lipid content, which is has a positive effect on the growth of the mycelia. Nowadays supplements are mostly soy-based materials, but corn flour, dried potato protein, peanut flour, meat and bone meal were used as well. Precautions need to be taken as supplemented compost can easily overheat. Excessive heating and the nutrient content is favorable not only for the cultivated mushroom, but for competitor fungi (especially the most dangerous molds such as Trichoderma aggressivum f. aggressivum and f. europaeum) as well. Today, several commercial supplements are available that can be used at spawning or at casing to stimulate mushroom yield.

In modern plants, from the pasteurization tunnels finished and spawned compost is transferred to bulk spawn run tunnels. The disadvantage of this method is that it increases the risk of infestation or unwanted pathogens and pests, thus higher level of sanitation is required. Phase II. compost can be sold directly to growers, who take it to their production rooms and have the compost colonized by the mycelia at the same room the cropping will take place. The risk of infestation is lower this way, but the 2 week long colonization takes up valuable space, which otherwise (by buying phase III. = bulk spawn run compost) could be utilized by cropping compost.

Tunnel phase II. composting coupled by bulk spawn run is a more automated and mechanized process that results a more uniform compost than any other technology. At the end of phase II. composting the water content is 65-70%. The compost has dark colour, it is easily torn and do not stick to the hand and most importantly it does not smell like ammonia at all. The quality is always checked in a laboratory and registered for quality control. In case of complains (or even law suits) they are helpful deciding whether problems during cultivation derive from compost quality or production errors.

The different compost types: Phase I., II., III. and IV.

The different compost types: Phase I., II., III. and IV.

Phase III.

Phase III. compost is colonized by the mycelia of the cultivated mushroom. Nowadays spawn run takes place in the compost plants in bulk spawn run tunnels, during which phase II. turns into phase III. (It can happen in the production area as well, if the grower buys phase II. compost). In 2011 90% of the total compost production was sold in 3rd phase in Hungary. Following casing, phase III. compost is ready for cropping.

Hygiene is especially important in and around the spawn run tunnels, and everywhere phase II. compost is moved through from the pasteurization tunnels to the spawn run tunnels. The tunnels and equipment (machines and protective clothing worn by workers) are previously sterilized, the air is filtered. Overpressure in the tunnel and working area prevents infestation after sterilization.

Phase II. compost is placed into the spawn run tunnels (which are basically are the same type of tunnels used for pasteurization in phase II. composting) in 3,0-3,5 m high piles. The process starts by equalizing the temperature and heating the compost up to 25-27˚C, which is held throughout the entire 14-16 days of colonization. Oxygen and CO2 levels and temperature are monitored, registered continuously and controlled if necessary.

Advantages of using phase III. compost:

- The grower saves 14-16 days time, which means a 20% shorter growing cycle (thus more cycles “fit” in a year). The costs of the 2 weeks spawn run are not on the grower.

- 20% more compost can be placed in the production area than in case of growing on phase II. compost.

- Hygiene is usually better in compost plants during colonization, thus the risk of infestation is lower.

- Phase III. compost spends shorter time in the production area, this way pests (especially mushroom flies – Sciaridae) don not have that much time to reproduce.

- Growers do not have to worry about the circumstances of spawn run: whether in the end quality will be good enough for successful growing or not. The quality of bulk spawn run phase III. compost is uniform and ensured.

- Higher yield can be picked from the same production area size in a year.

Disadvantages of using phase III. compost:

- The price of phase III, compost is higher than of phase II.

- The crop appears at the same time (one flush is picked for a shorter period, but more mushrooms are picked by one picking), which makes organization of work more difficult.

- Phase III. is more easily to overheat than phase II. compost.

At the end of phase III., compost can be filled into plastic (polyethylene) bags, which are then transported in cellars or mushroom houses, where the cropping will take place. Probable temperature changes (in the summer: overheating; in the winter: freezing of the peripheral bags) of the compost has to be taken into account during transportation of phase III. compost. In the summer, the 25-27˚C compost could easily overheat if transported long term without air-conditioning. Above 30˚C mycelia suffers damage. 24-48 hours after arrival the bags have to be cased (with usually 4-5 cm thick casing).

Bag, block and bulk compost forms transferring

The most modern method is when compost is sold bulk, and then transferred to Dutch-type growing houses with special, air-conditioned trucks. A machine fills the compost into shelves of the Dutch-houses directly from the trucks. Another machine at the same time puts casing on the freshly filled shelves.

Button mushroom compost production and growing

Use of spent mushroom compost

Post-crop mushroom compost (also called as spent mushroom compost in case of button mushroom and spent substrate in case of shiitake and oyster mushroom) is a material left over after the crop has been terminated. It consists of compost and casing (basically peat moss) with mycelia in them. It is not waste, since it has many valuable nutrients and a very good structure, which makes it a valued product in horticultural industry. (The possible uses of spent mushroom compost are in the focus of many researches in the USA. Information is available on the following link - SMS_Brochure.pdf és Spent_Mushroom_Substrate.pdf). Spent composts are long time used in gardens or nurseries that are close to mushroom growing facilities. Mineral and nutrition contents of some post-crop mushroom composts are shown on next table.

Mineral and nutrition contents of some post-crop mushroom composts

|

Minerals and nutrients |

Dry matter (%) |

||

|

calcium |

2,21 |

2,02 |

2,46 |

|

potassium |

4,84 |

6,21 |

5,38 |

|

magnesium |

0,74 |

0,66 |

0,65 |

|

natrium |

0,19 |

0,19 |

0,23 |

|

iron |

0,17 |

0,15 |

0,06 |

|

aluminum |

0,25 |

0,25 |

0,14 |

|

ammonia-nitrogen |

0,04 |

0,05 |

0,06 |

|

total nitrogen |

2,89 |

2,39 |

2,55 |

|

salinity (EC) (mS/cm) |

14,0 |

11,4 |

12,2 |

|

water content |

67,7 |

64,4 |

69,6 |

|

pH |

6,5 |

6,5 |

6,2 |

The positive effects of spent composts and substrates on the quality and nutritional composition of soils.

- The humus content increases.

- Spent composts increase the water absorption of light soils.

- The soil structure improves, heavy soils loosen up and buffer capacity grows.

- The microbe activity increases.

- Yield could improve.

- Could be used for mulching, which is bots beneficial for the nutrient and water content of the soil.

Since salinity of post-crop composts is quite high, using them in sensitive vegetable (e.g. lettuce and pepper) production is not recommended. Due to environmental regulations, disposal of these materials raises issues. They can be composted again, which is a long (2 years) process and results a valuable product with a structure similar to peat moss. Mixed with real peat, the material can be used as casing. Another possible use is to burn spent compost in thermal power stations. The disadvantage is that the material still contains around 60% water and has a high ash level.

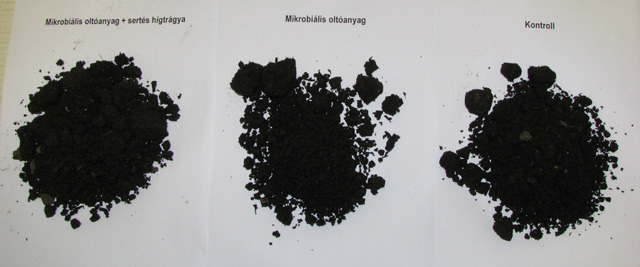

The structure of spent compost after two years of “composting”

Spent composts and substrates require special handling, as they are sources of pests and parasites and if left close to the production area, could endanger the next cycle. Since only two chemicals are allowed against pests and pathogens in mushroom production, there are hardly any residues left in spent mushroom composts. The most modern method is applied in Dutch-type mushroom houses, where after the last flush, the growing room is closed off and the whole room is pasteurized with steam. This final pasteurization is designed to destroy any pests that may be present in the compost or casing, thus minimizing the likelihood of infesting the next crop.

Test your knowledge!

- What are the ingredients of button mushroom compost?

- What are the steps of composting?

- What is the difference between phase II. and phase III. composts?

- How can we use spent mushroom composts and substrates?

References

Babcock, G. (2004): Reuse of Substrate in Specialty Mushroom Production. Mushroom Science XVI. Proceedings of the XVIth International Congress on the Science and Cultivation of Edible and Medicinal Fungi. (Miami, 14-17 March, USA), The Pennsylvania State University, 559-563.

Beyer, D.M. (2001): Spent Mushroom Substrate. Fact Sheet, http://mushroomspawn.cas.psu. edu./Spent.htm

Buth, J. (2007): Influences and parameters in composting. Mushroom Business, 25: 12-13.

Derks, G. (1992): The high-yielding, simple indoor composting system. Mushroom Journal, 510: 14-15.

Eger, G. (1972): Experiments and comments on the action of bacteria on sporophore initiation in Agaricus bisporus. Mushroom Science, 8: 719-725.

Fehérvári-Póczik, E., Slezák, K., Győrfi, J. (2005): Letermett csiperkegomba táptalaj keverékek hatása a kígyóuborka termésmennyiségére és a termés minőségére. Erdei Ferenc III. Tudományos Konferencia, Proceedings, II: 690-694.

Fehérvári-Póczik, E., Slezák, K., Győrfi, J. (2006): Nutrition content of spent mushroom compost before and after utilization in vegetable forcing experiments. International Journal of Horticultural Science, 12, 1: 53-55.

Fergus, C.L. (1964): Thermophilic and thermotolerant moulds and actinomycetes of mushroom compost during peak heating. Mycologia, 56: 267-284.

Fergus, C.L., Amelung, R.M. (1971): The heat resistence of some thermophilic fungi on mushroom compost. Mycologia, 63: 657-679.

Fermor, T.R., Wood, D.A. (1981): Degradation of bacteria by Agaricus bisporus and other fungi. Journal of General Microbiology, 126: 377-387.

Flegg, P.B. (1995): „Indoor-Kompostierung. Der Champignon, 384: 74-76.

Geösel, A., Pap, Z., Y. E. Bayoumi, Lestál, G., Győrfi, J. (2009): Letermett gombakomposzt, mint palántanevelő közeg vizsgálata. Kertgazdaság, 41, 3: 3-9.

Gerrits, J.P. . (1992): Trends in composting. Mushroom Journal, 508: 46-51.

Gerrits, J.P.G. (1974): Development of a synthetic compost for mushroom growing based on wheat straw and chicken manure. Netherlands Journal of Agricultural Science, 22: 175-194.

Gerrits, J.P.G. (1977): The significance of gypsum applied to mushroom compost, in particular in relation to ammonia content. Netherlands Journal of Agricultural Science, 25: 288-302.

Gerrits, J.P.G. (1985): Further studies on factors in bulk pasteurization and spawnrunning. Mushroom Journal, 161: 169-174.

Győrfi, J. (2003): Csiperketermesztés nemcsak vállalkozóknak. Szaktudás Kiadó Ház, Budapest, 5-199.

Győrfi, J. (2010): A csiperkegomba (Agaricus bisporus) termesztése. (In: Győrfi, J. (szerk): Gombabiológia, gombatermesztés. Mezőgazda Kiadó, Budapest,139-187.

Győrfi, J., Maszlavér, P. (2002): Technológiai forradalom a csiperkekomposzt készítésében. Kertgazdaság, 34, 1:, 64-69.

Győrfi, J., Geösel, A., Lestál, G., Póczik, E. (2008): A letermett komposztok összetételének változása. Proceedings of The 15th Symposium on Analytical and Environmental Problems, (Szeged, 22 September, 2008): 66-68.

Győrfi, J., Maszlavér, P., Fehérvári-Póczik, E. (2004): A letermett csiperkekomposzt elemösszetétele és hasznosításának lehetőségei. Proceedings of „The 11 th Symposium on Analytical and Environmental Problems”, (Szeged, 27 September, 2004): 257-261.

Győrfi, J., Maszlavér, P., Póczik, E., Slezák, K., Terbe, I. (2003): Palántanevelési kísérletek letermett csiperkekomposzt takaróanyag rétegén. Kertgazdaság, 35, 4: 37-44.

Lohr, V.I., Wang, S.H., Wolt, J.D. (1984): Physical and chemical characteristic of fresh and aged spent mushroom compost. Horticultural Science, 19: 681-683.

Maher, M.J. (1994): The use of spent mushroom substrate (SMS) as an organic manure and plant substrate component. Compost Science & Utilization, 2: 37-44.

Morrisey, L. (1995): Benefits of Phase III (spawn-run) compost to the mushroom grower. Proceedings of 11th Irish National Mushroom Conference, 38-39.

Nagai, M., Sato, T., Enei, H. (2004): Bioremediation by Laccases from Lentinula edodes. Proceedings of the XVIth International Congress on the Science and Cultivation of Edible and Medicinal Fungi. (Miami, 14-17 March, USA): 573-578.

Oei, P. (2003): Mushroom cultivation. Backhuys Publishers, Leiden, 1-429.

Philippoussis, A., Zervakis, G.I., Diamantopoulou, P., Ppapadopoulou, K., Ehaliotis, C. (2004): Use of Spent Mushroom Compost as a Substrate for Plant Growth and Against Plant Infections Caused by Phytophthora spp. Proceedings of the XVIth International Congress on the Science and Cultivation of Edible and Medicinal Fungi. (Miami, 14-17 March, USA): 579-584.

Rácz, J., Koronczy, I.-né (2001): Hogyan termesszünk csiperkegombát? Quality Champignons Kft., Kerecsend.

Riahi, H., Arab, A. (2004): Spent Mushroom Compost as an Alternative for Casing Soil. Proceedings of the XVIth International Congress on the Science and Cultivation of Edible and Medicinal Fungi. (Miami, 14-17 March, USA): 585-589.

Rinker, D.L., Zeri, S.W.K. (2004): Recycling of Spent Oyster Mushroom Substrate. Mushroom Growers Handbook 1. Oyster Mushroom Cultivation, Mushworld, 193-197.

Sinden, J.W., Hauser, E. (1950): The short method of mushroom composting. Mushroom Science, 1: 52-59.

Sinden, J.W., Hauser, E. (1953): The nature of the composting process and its relation to short composting. Mushroom Science, 2: 123-131.

Sinden, J.W., Schisler, L.C. (1962): Nutrient supplementation of mushroom compost at casing. Mushroom Science, 5: 267-280.

Stanek, M. (1974): Bacteria associated with mushroom mycelium (Agaricus bisporus(Lang.) Sing.) in hyphosphere. Mushroom Science, 9, 1: 197-207.

Straatsma, G. (2004): Processing and Composition of Mushroom Compost. Mushroom Science, XVI: 241-246

Turner, E.M. (1974): Phenoloxidase activity in relation to substrate and development stage of the mushroom Agaricus bisporus. Transactions of the British Mycological Society, 63: 541-547.

van Griensven, L.J.L.D. (1988): The Cultivation of Mushrooms. Mushroom Experimental Station, Horst.

Van Horen, L.G.J., van Rijswick, C., Bass, E. (2008): Economic Developments in the Mushroom Industry. Sixth International Conference on Mushroom Biology and Mushroom Products. Bonn, Germany. Programme and Abstracts, 34.

Van Zaayen, A., Rutjens, A.J. (1981): Thermal death point for two Agaricus species and for the spores of some major pathogens. Mushroom Science, 11: 393-402.

Wood, D.A. (1976): Primordium formation in axenic cultures of Agaricus bisporus (Lange) Sing. Journal of General Microbiology, 95: 313-319.