Primary and secondary processing, extraction, storage and trading of medicinal plants

Authors: Szilvia Sárosi and Zsuzsanna Pluhár

Generally, the first processing operations which are done immediately after harvesting are called primary processing. It is usually carried out by the producer himself. The aim of primary processing is to produce a high quality drug able to be used as basic material for the secondary processing; thus it is free from alien plant parts and other contaminations, it contains acceptable amount of active compounds and it can be stored for longer periods without quality loss. The most frequent methods of primary processing are drying and essential oil extraction.

PRIMARY PROCESSING OF MEDICINAL PLANTS

Drying

Preparation of drying

One of the most important primary processing methods is the conservation of plant parts by drying. However, before drying some additional procedures need to be carried out, such as stripping, cleaning, cutting, fermentation and withering.

Stripping is necessary, if the used plant part is the leaf; therefore the presence of stem is not desired in the drug (e.g. Melissa officinalis – Lemon balm, Urtica dioica – Great nettle).

Since the harvested plant part can be contaminated by alien plant parts, dust and sand, we need to pay attention to its cleaning, which is usually done by washing (valerian, angelica), screening (chamomile) or peeling (soap-root, ginseng).

Screening machine (photo: Varga, 2012)

Cutting can be carried out either before or after drying. In the case of roots it is advised to be done before drying, thus the uniform size will assure a more efficient drying. The way of cutting is characterize the different drug types, for example in the case of soap root (Saponariae albae radix) rounded slices are frequent, while liquorice (Liquiritae radix) is cut into small cubes.

In certain cases fermentation is carried out just before drying (e.g. black tea production) mainly because of its significant effect on the active compounds’ composition.

As a pre-drying process withering can be used if the plant material contain milky sap, or the surface of the leaves are too wet (e.g. fresh tea leaves).

Drying methods

One of the most important primary processing methods is drying; at the end of this procedure the moisture content of the drug cannot be more than 10-14 %. Therefore after drying the water content is reduced to a limit where the plant parts will be able to be stored for longer periods. Drying has been used for centuries to preserve the quality parameters of medicinal plants and spices, and still nowadays this method can be regarded as the simplest one among the preservation techniques. Therefore, more than 400 different types of drying machines can be found in the market according to the literature data. Since drying is an energy consuming process (for the evaporation of 1 kg water 10.000 KJ energy is necessary), new types of equipment have been developed using natural sources of energy (sunlight), or alternative energy (heat, coming out from ice-rooms).

Drying can be done naturally or artificially. Natural drying is the simplest and cheapest way of the plant material’s preservation. We need only an airy space protected from sunlight, or in certain cases we can dry the plant material directly under the sunlight at the growing area (e.g. fresh flowers of safflower). However, the drying parameters cannot be controlled (temperature, air-humidity, air-movement); thus the weather conditions influence the length and effectiveness of the drying process (it can take several weeks). The plant material can recollect the moisture easily from the air; therefore deteriorating processes cause the loss of the active compounds and disadvantageous changes in the external properties (colour, smell, taste). Solving this problem new type of natural dryer has been developed in Germany called solar dryer, where the energy of sunlight is used as an additional natural energy source.

Natural way of drying (photo: Varga, 2012)

On the contrary of natural drying, in the case of artificial drying most of the drying parameters are controlled. The air temperature is the most important parameter having significant effect on the active compounds. Based on the air temperature cold- (only the movement of the drying air is controlled), warm- (30-80°C), and hot-air drying (200-1000°C) can be differentiated. In the case of those plant parts rich in volatile compounds the advised drying temperature is 30-50°C, referring to the glycoside type active constituents drying process is usually carried out at 50-60°C, while plants containing alkaloids are the less sensitive ones to the drying temperature (60-70°C). Hot air drying is used only in the pharmaceutical industry. The homogenized plant material spends only a few minutes in the hot air, therefore its surface will not be heated more than 60-70 °C. The method is rather fast, however it needs a lot of energy, and very careful plant preparation. The bigger plant parts can be burnt; however, the small ones can remain wet.

Warm-air drying is the main preservation method for medicinal and aromatic plants. The two, most well-known varieties of warm air driers are the plate chamber dryer and conveyor dryer.

Plate chamber dryer (photo: Varga, 2012)

Binder-type conveyor dryer (photo: Varga, 2012)

Freeze-drying or lyophilisation is also an artificial drying technique, and it is becoming more widespread also in the case of medicinal and aromatic plants.

Freeze dryer (photo: Sárosi, 2012)

The price of a new freeze-dryer and its operation cost is high, and in several cases the process causes significant loss of the active compounds, or disadvantageous changes in the composition. Therefore, even if the lyophilised drugs are found to be the most preferable ones by the consumers based on their organoleptic parameters, their quality usually do not meet the requirements of the official formulas (e.g. pharmacopoeias). Thus, more scientific results would be necessary to optimize this method, and to precisely describe in which cases it is advisable to be used.

Freezing is an alternative method that can be applied to the preservation of medicinal plants as well. The vitamin C content of the fast-frozen plant materials is almost equal to the fresh fruits; however the freezing process causes serious damage to the plant tissues and significant loss of other active compounds.

Effect of the different drying methods on the drug quality

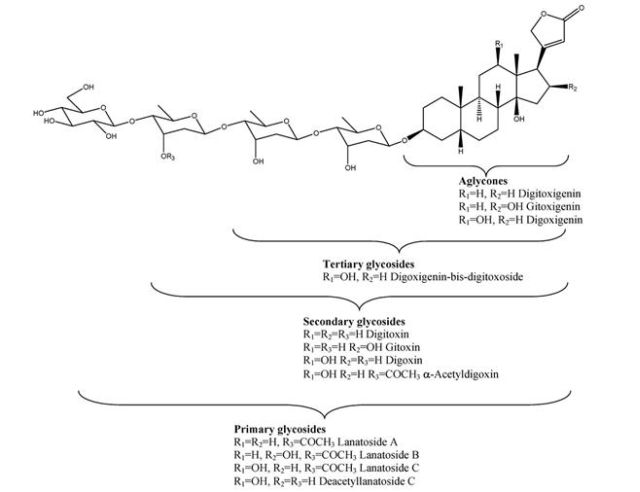

In this chapter a summary is given referring to the main changes in the active compounds caused by the different drying-preservation techniques. In the case of sugar-containing plant parts (oligo-and polysaccharides, mucilage, etc.) the optimal temperature of drying is 50-60 °C. However, not only the conventional drying methods have been tested, the possible usage of freeze-drying was also evaluated in the case of foxglove species (Digitalis lanata L., Digitalis purpurea L.) containing cardiac-glycosides.

Chemical structure of cardiac glycosides (according to Pellati et al., 2009)

Based on the type and number of sugar parts, the effect of the cardiac glycoside is different; therefore the decomposition of the initial cardiac glycosides can significantly change the therapeutic effect of the final material. If the drying process is fast (by using hot air drying), or carried out in aerobe circumstances the enzyme activity is successfully blocked, and the Lanatosid-C content can be preserved in much higher amounts. On the contrary, if the drying process is slow (cold air drying) in anaerobe conditions, the sugar parts are decomposed, and after drying the plant material will be rich in digoxin. Thus, the final purpose determinates the way of the primary processing. Freeze-drying can be taken in the second group, since it is a long (at least 72 hours) process, carried out at very low temperature. However, against the expectations, in the final plant material not digoxin, but its derivative – acetyl-digoxin – was found. Since acetyl-digoxin does not have the same effect as digoxin, the usage of lyophilisation is not advised in the case of foxglove species.

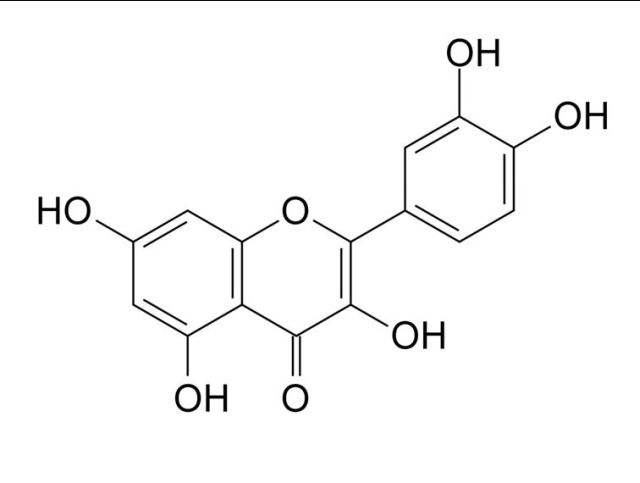

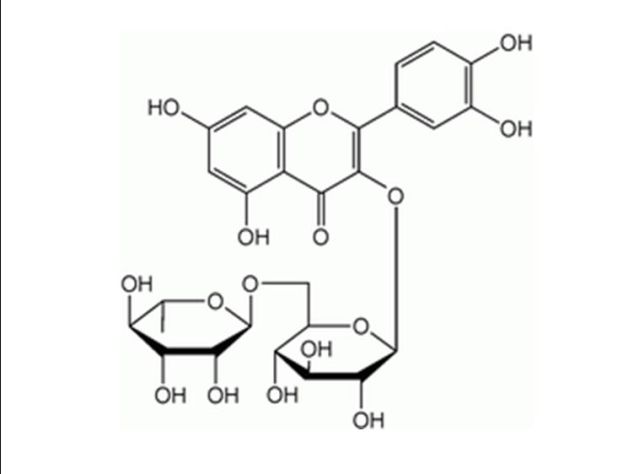

In the following group phenoloids are discussed. A lot of active compounds can be classified as phenolic compounds; among them the most important ones are flavonoids, tannins, phenol-glycosides, phenolic acids. Flavonoids are widely distributed in the plant kingdom, especially as plant pigments. They can be found as glycosides and as aglycones as well; therefore similar to the cardiac glycosides the type and number of the sugar parts can influence significantly the therapeutic effect. For example the ratio of quercetin (aglycone) and its glycoside derivate rutin (quercetin-3-O-rutinoside) can be affected by the different preservation methods in the case of onion. Quercetin is known as perspective anti-cancer (real clinical data is missing) and anti-viral agent, while rutin has a beneficial effect on the cardio-vascular system (it decreases capillary permeability, also know as vitamin-P). During the primary processing of onion warm air drying resulted in higher amount of quercetin, while freeze-drying was more advantageous referring to the rutin content.

Structure of quercetin (according to Wikipedia)

Structure of rutin (according to Wikipedia)

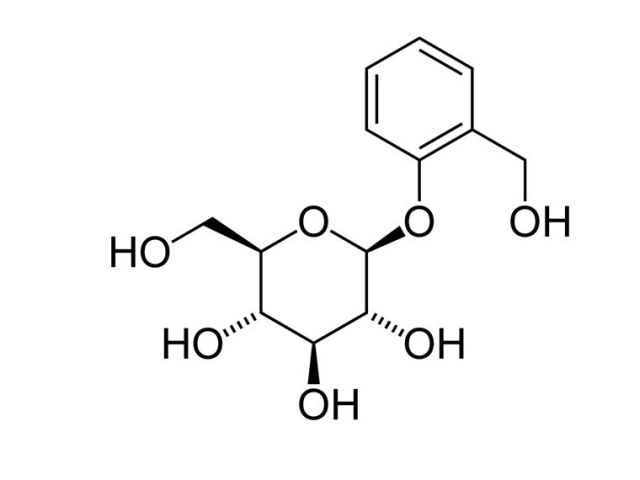

The bark of white willow contains salicin (phenol-glycoside), known as the basic initial compound of Aspirin. It has an anti-inflammatory effect, and has been used in the folk medicine for centuries. The bark needs to be dried only when its moisture content is more than 12-14%. Although the simplest way is natural drying, other preservation methods (warm-air drying, freeze-drying, and freezing) have also been tested on the quality parameters of the bark. Drying at 70°C caused significant loss in the salicin content, as well as freezing. Freeze-drying can be regarded less damageable; however none of these artificial methods produced the same results as natural drying.

Structure of salicin (according to Wikipedia)

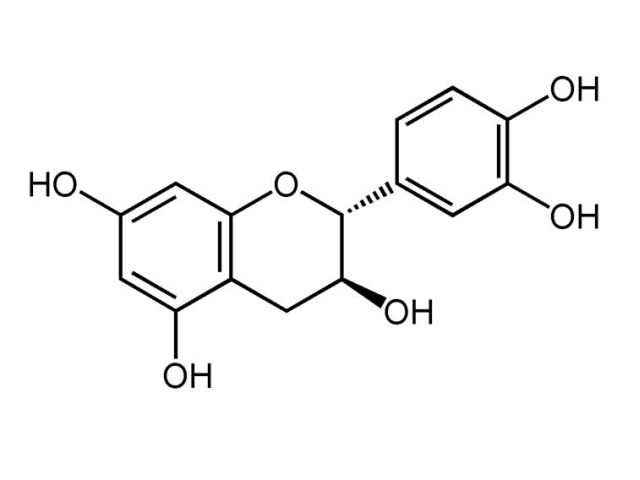

As it has already been mentioned the individual colour, taste and smell of black and green tea is due to the different primary processing. During black tea production before drying tea leaves are fermented (leaves are rolled, crushed, the liquids react with the oxygen), while the enzymes are blocked by steaming in the case of green tea production. Therefore the active compounds of these tea types are also different; green tea is rich in catechins, while black tea contains tannins. Even if these active constituents are similar, their effect is different; catechins, especially epigallocatehin gallate (EGCG) are one of the strongest and most stable natural antioxidants. Tannins also have antioxidant effect; however, they are better known for their beneficial cardiovascular properties. Of course not only the fermentation can cause changes, the way of preservation can also influence significantly the quantity of these compounds. Too high temperature (above 60°C) and freezing have disadvantageous effect; however, natural and cold air drying, furthermore lyophilisation causes less damage.

Structure of catechin (according to Wikipedia)

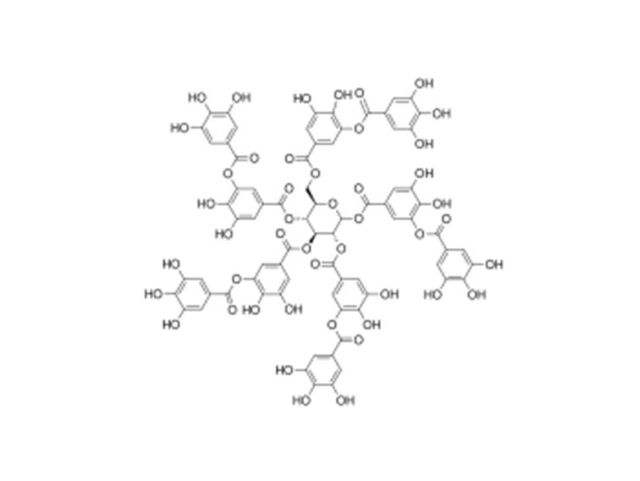

Structure of tannins (according to Wikipedia)

Rosmarinic acid, also known as a strong and stable natural antioxidant, is also sensitive to the high temperature and freezing; while freeze-dried spices (rosemary, sage and thyme) preserve their initial rosmarinic acid content in a high percentage.

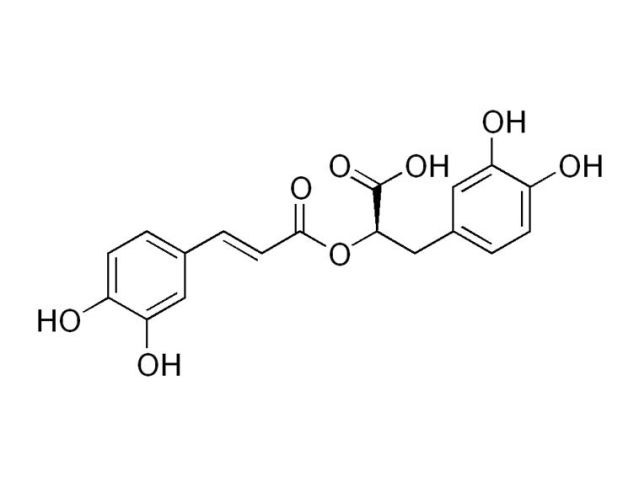

Structure of rosmarinic acid (according to Wikipedia)

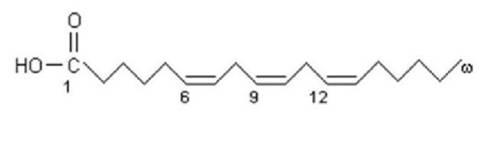

In the following group of active compounds fatty acids will be discussed. Usually, they are found in fruits and seeds as important nutrients feeding the sprouts. As in all drug types, the prescribed maximum water content of the fruits and seeds are 14 %. If the plant material contains higher amounts of water, it needs to be dried. Unsaturated fatty acids are sensitive to the air temperature and the length of the drying. Therefore it is advisable to apply lower temperature (not more than 40°C); however natural drying needs to be avoided, since it can take several weeks (too long period), and the decomposition of fatty acids is initiated.

Structure of a well-known unsaturated fatty acid – gamma-linolenic acid (according to Wikipedia)

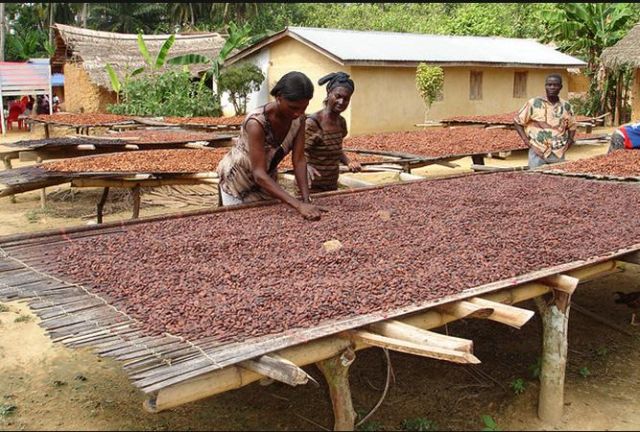

Volatile fatty acids play an important role during the fermentation of cocoa beans. However, their content needs to be reduced during the drying process, because their presence in the final product can be detrimental to the cocoa quality. The easiest way of their elimination is to apply natural drying (sun drying). According to the literature data this method cannot be substitute by artificial drying methods (warm-air drying), because the decomposition of the volatile fatty acids is not acceptable.

Sundried cocoa beans in Africa (http://www.flickr.com/photos/19998197@N00/3010666896/)

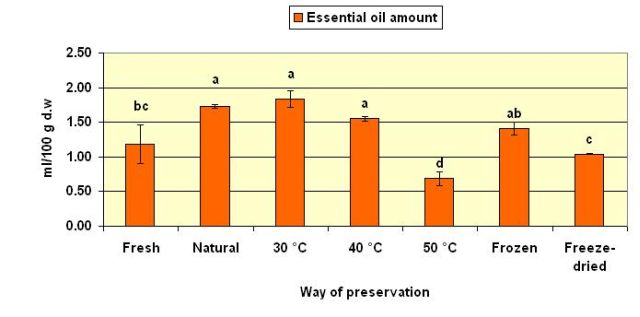

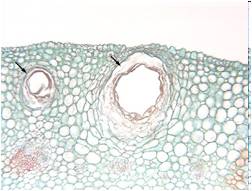

Several active compounds can be found among terpenoids, such as volatile oil components. As we have already mentioned plant parts containing essential oil are more sensitive to the drying temperature, therefore it is advised not to apply more than 40°C during the primary processing. Freezing and freeze-drying can also cause significant damages to the essential oil glands, which are presented by Figure in the case of garden thyme.

Essential oil content of differently preserved garden thyme samples (according to Novák, 2011)

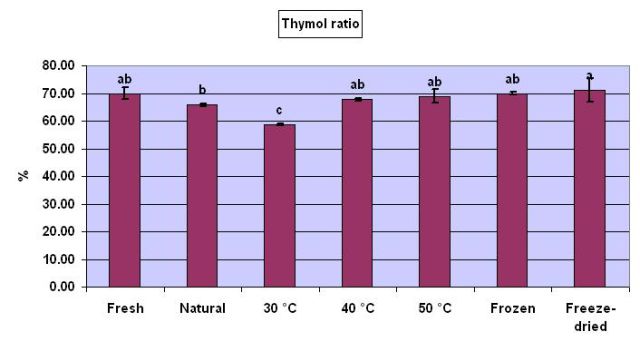

Not only the quantity parameters of essential oils are influenced by the primary processing methods, the essential oil composition can also change. Referring to the above mentioned sample – garden thyme – the ratio of the main compound (thymol), which is mainly responsible for the characteristic taste and smell of the drug, will decrease, if the drying takes too long time (cold-air drying, natural drying). On the contrary, fast drying on higher temperature, freezing and lyophilisation preserve more effectively the initial proportion of thymol in the distilled essential oil, that is comparable even to the fresh samples. However, it needs to be emphasized that huge differences can emerge among the plant species, even if they are members of the same plant family.

Ratio of thymol in the essential oil of differently preserved garden thyme samples (according to Novák, 2011)

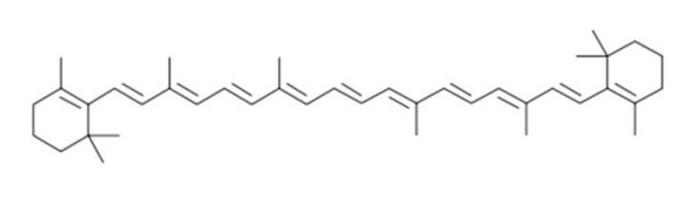

Carotinoids (e.g. beta-carotene) giving orange colour to carrot, pumpkin or marigold (Calendula officinalis), and the red coloured licopin found in the tomato, are also terpenoids (they are tetraterpenes). It is easy to be noticed, that during cooking, baking, their colour intensity is decreasing, especially compared to the fresh plant materials. Because of the heat, significant decomposition of carotinoids can be detected. Therefore, in the case of marigold it is advised to apply fast drying at 70-80°C, or sun drying. Alternatively freeze-drying can be also applied, although the decomposition of carotenes is more significant and in the final product mainly lutein is found.

Structure of β-carotene (according to Wikipedia)

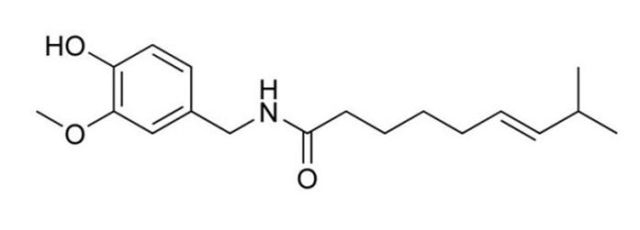

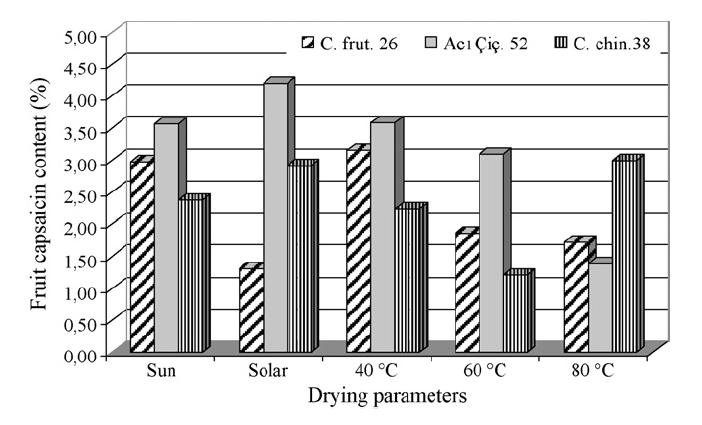

Finally, let’s see the N-containing active compounds, where several alkaloids are found. Capsaicin, which gives pungent taste to chilly paprika, is a well-known proto-alkaloid constituent. It has several therapeutic properties, it is used as a topical analgesic, it has tonic, antiseptic and carminative effect; it is useful against rheumatism, arthritis, neuralgia, lumbago and spasm. Conventionally, Hungarian paprika is dried in the harvesting territory, under the direct sunlight. According to the literature data it is useless to apply artificial drying, because the primary processing cannot affect significantly the capsaicin level of the fruits; the cultivation techniques and the genetic background (different cultivars) are the main influencing factors.

Structure of capsaicin (according to Wikipedia)

Effect of the different drying methods on the capsaicin content of pepper (according to Yaldiz et al., 2010)

Natural drying of Hungarian paprika (http://www.panoramio.com/photo/19529119)

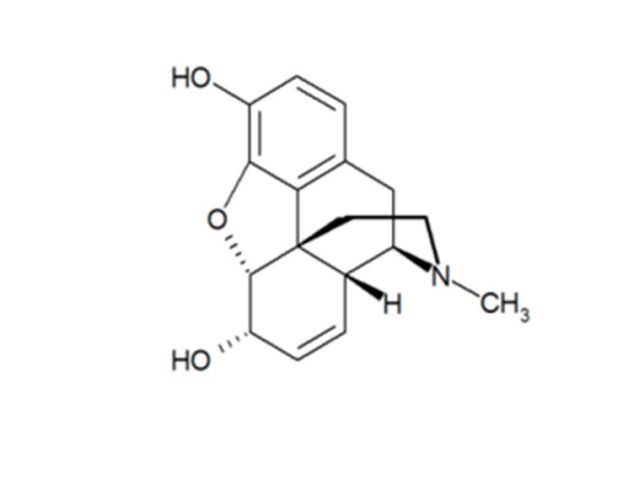

Among poppy alkaloids morphine is the most well-known for its strong analgesic effect. Although, generally alkaloids are less sensitive to the temperature during drying, the amount of morphine can decrease by 10-11% above 40°C. Also natural drying of the capsules is advised to be avoided, since it is a too long process causing significant loss in the alkaloid content.

Structure of morphine (according Wikipedia

Summarizing the results it is obvious that the too high drying temperature can significantly damage the active compounds; also lyophilisation cannot be used in all cases, even if it is becoming more widespread in the case of medicinal and aromatic plants. The possible usage of freeze-drying according to the literature data is demonstrated in Table.

Possible usage of lyophilisation in the case of medicinal and aromatic plants

Lyophilisation can be advised Lyophilisation need to be avoided

Plant parts containing flavonoid glycosides Plant parts containing cardiac glycosides

Plant parts containing phenol glycosides Plant parts containing unsaturated fatty acids

Plant parts containing tannins Plant parts containing low amount of essential oil

Plant parts containing rosmarinic acid

Plant parts containing colouring agents

SECONDARY PROCESSING OF MEDICINAL AND AROMATIC PLANTS

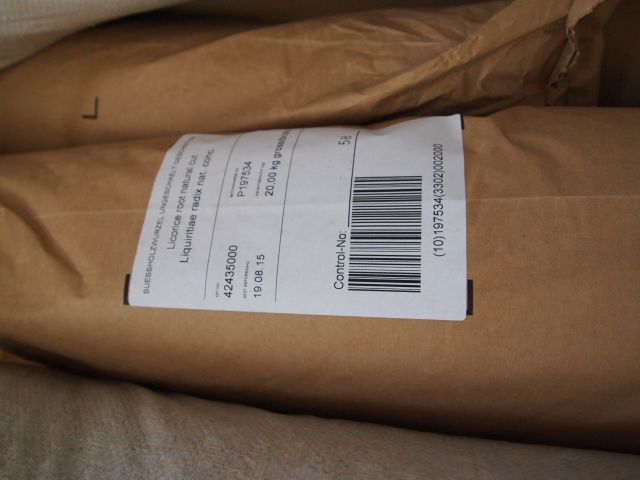

The final material of the primary processing (drug) is becoming an end-product during the secondary processing where the main technical operations are the following: selection, slicing-cutting, crumbling, grinding, making tea mixture, making tea filters, packaging. While primary processing is usually done by the producer, the secondary processing is carried out in the trading companies. Thus, the dried raw materials are usually stored for a short period before the secondary processing. Proper labelling needs to be taken on every batch indicating the name, origin, weight, barcode of the plant material as well as the date of arrival.

Storage of dried plant materials before the secondary processing (photo: Varga, 2012)

Labelled packaging in the warehouse (photo: Varga, 2012)

The dried raw materials are re-selected on white coloured picking-belts (length: 5-7 m, width: 70-80 cm, speed: 1-10 m/min., by hand, or by using riddler machine to remove alien plant parts or damaged drugs.

Selection of chamomile flowers by using picking-belt (photo: Varga, 2012)

Selected, homogeneous elder flowers (photo: Sárosi, 2012)

After the selection, cutting or slicing can be done according to the requirements. If the valuable plant parts are flowers or leaves (e.g. chamomile, garden thyme) their removal is easily done by a crumbling machine.

Powdered plant material is usually necessary for making capsules, tablets or spice mixtures. For this purpose several types of grinding machines can be used (hammer-, cutting- and turbo-mills.

Crumbling of chamomile flowers from the stem (photo: Bernáth, 2000)

Bauermeister type hammer-mill (www.bauermeisterusa.com)

The end-products need to be sterilized before packaging. For this purpose steaming machines can be used.

Steaming machine used for the sterilization of plant materials, Herbária Ltd. (photo: Pluhár, 2011)

Making tea mixtures can be automatized as well. The plant materials are put in separated cartridges on the top of the machine.

The final materials can be packed into bags, filters or capsules, it depends on the demands. Obviously all technical operations are automatized. The tea-filters, capsules are packed in bigger packages suitable for the transportation.

Tea filtering machine (fotó: Sárosi, 2012)

Capsule making machine (photo: Sárosi, 2012)

Packaging machine (photo: Sárosi, 2012)

EXTRACTION TECHNIQUES OF MEDICINAL AND AROMATIC PLANTS

Utilization of medicinal and aromatic plant extracts has become very widespread in food, perfumery and pharmaceutical industries. Furthermore, these products are extensively applied as active agent of household chemicals as well as used for phytotherapeutical and aromatherapeutical purposes.

It was proven that the herbal extracts have several advantages compared to the drugs and spices preserved by drying. The most important comparative benefits are as follows:

-

more concentrated odour, taste, aroma and active compound ratio,

-

higher purity (free of microbial contamination, dust, etc.)

-

easier dosage and administration,

-

valuable compounds are included in a lower volume during storage

-

better bioavailability after ingestion in the human body, with elongated effect.

Standardized Ginkgo biloba leaf extract encapsulated ( http://www.rumexextracts.com/en/index.html )

Resources of plant extracts are different plant parts, high in valuable compounds accumulated in special structures. Grouping of stuctures producing active substances is important from industrial point of view and the appearance of them can be:

-

Superficial (glands, trichomes, etc.): Lamiaceae, Verbenaceae, Geraniaceae, Asteraceae, etc.

-

Internal (cavities, cells, tissues, oil or laticiferous ducts, etc.): other plant families (e.g. Apiaceae, Rutaceae, Papaveraceae, etc.)

Lamiaceae type peltate glandular trichomes on the upper leaf surface of Thymus vulgaris L. (Photo: Pluhár, 2006)

Several type of extracts can be obtained from the same plant raw material, from the simple tea preparation (hydroextract) to the more sophisticated, well administered herbal medicines. In general, the more concentrated extracts possess higher value, however, the process of manufacturing is more costly as well.

In some cases the extraction procedure is carried out in rural areas near by the growing site, as in the case of water distillation of the freshly harvested herbs. However, specialized companies dealing only with extraction has become more widespread, recently.

The latter ones use complete processing lines and are able to prepare different kinds of extracts according to the industrial orders. In some extraction plants end-produts are also manufactured and the procedure is completed by packing of pills or capsules. Introduction and application of quality assurrance systems (ISO, GMP, etc.) is of primary importance at the extracting and product manufacturing companies.

Main tasks of the companies specialized for extract manufacturing (Source: http://totalhealthnd.com )

Basic terms

In a broader sense, extraction is the process of obtaining extractable compounds from the plants by chemical, physical or mechanical ways. In a narrower sense, this category is practically used for solvent extraction only. The selection of solvent is of key importance: this is a liquid, a supercritical fluid or a liquified gas, which is used for extraction of compounds. The final product of the extraction is the extract, which can be obtained by solvent from natural materials after filtration and evaporation of the solvent. Its composition is highly dependent on the method and conditions of extraction. Increasing concentration of the end product requires the most sophisticated and specific processing technics. Highly concentrated/refined extracts represent high value but require higher processing costs as well.

Industrial scale extraction methods

Theoretical bases of the industrial scale extraction procedures have been enlarged during centuries, however, quite frequently, a developed version of the original process is still considered to be the most effective method (e.g. in the case of cold pressing or distillation). Nevertheless, in the last decades many new methods have been developed and become widespread in this field. Therefore, the separation of conventional and modern extraction procedures cannot be regarded as strict or definitive, either.

Cold pressing, hydrodistillation, extraction with organic solvents and enfleurage can be assigned as conventional industrial scale extraction methods. Among modern technologies, mobile and turbodistillation, subcritical liquid extraction, supercritical fluid extraction, microwave extraction and sonication can be mentioned. In this chapter, the most important and extensively used large scale extraction procedures will be presented.

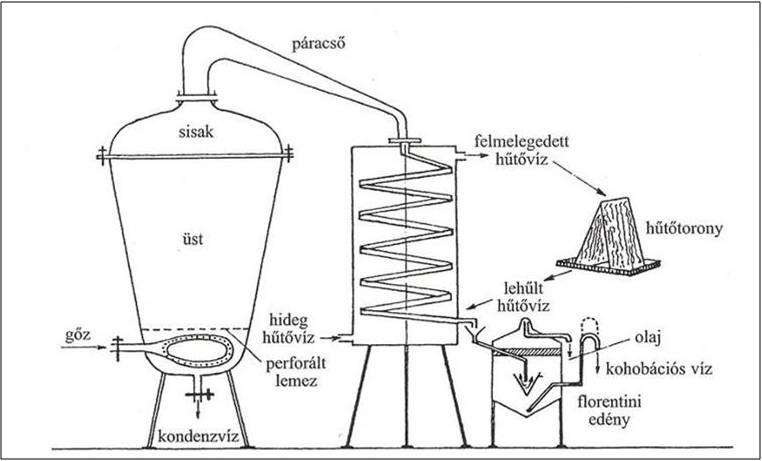

Distillation

Distillation is a heat-dependent extraction and refining process, during which the liquids are evaporated at their boiling points, and then the steam is transformed again into liquids in the condenser by cooling. Afterwards, the liquids involved can be separated. This method is used by distillation plants specialized for extraction of volatiles from different plant organs. As a result of the procedure, the essential oil compounds of high boiling points (250-300°C) can be extracted below 100°C and at athmospheric pressure, by means of steam.

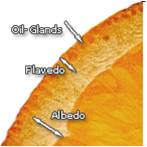

Essential oil is an extraction product obtained from a natural raw material of plant origin either by steam distillation, or by mechanical processes from the epicarp of Citrus fruits, or by dry distillation, after separation of the aquaeous phase, if any, by physical processes (decantation, filtration, centrifugation). Raw material of steam distillation can be fresh or dried plant parts being rich in essential oils.

Types of hydrodistillation are water-, water and steam-, or steam disitillation (steam distillation is used in 90%). A simple distillation unit involves a furnace (heat source), a distillation still, a steam pipe, a condenser and the essential oil separator (Florentine flask).

Leaf surface of peppermint with peltate glandular trichomes (after Svoboda et al. , 2000 nyomán: http://www.moleskinerie.com/2004/07/secretory_struc.html )

Fresh plant parts are prepared to distillation by chopping (flowering aerial parts), cutting into slices (roots) or crunching (fruits and seeds). Usually, the chopping is made by the harvester (e.g. dill, mint, clary sage), while the roots (e.g. lovage) are cut and layered by straw within the distillation still. Fruits and seeds (e.g. coriander, caraway) are roughly ground right before supplying into the still.

Steam distillation is the most common method of extracting essential oil on a commercial scale (80-90%), where fresh plant material is loaded onto a perforated grid or in a basket of the empty still (volume: 3-5 m3) to ensure uniform distribution of the steam. Steam is generated in a separate boiler or steam generator (140-170°C) and is injected below the plant material (→100°C). Pessurized dry steam flows in the direction of less resistance, distributing uniformly in the still body. Time and energy efficiency are among the advantages of the procedure. It provides control of the distillation rate and the pressure, consequently the quality is quite consistent and repeatable. However, high capital expenditure (investment) is necessary for the installation of the equipment. The cooling water consumption is considerable (2000 kg/h for 300 kg plant) and micropollution is observed by outgoing cooling water of high temperature (70°C) as well.

Diagram of the steam distillation process and the parts of the equipment ( http://www.anandaapothecary.com/articles/make-essential-oils.html )

The most important ways of improvements concerning distillation are as follows:

-

Mobile distillation unit, where the freshly harvested plant material is loaded into the mobile still body with a steam inlet system, after wilting and chopping. The mobil still body is taken to the distillery, where it is connected to the steam generator and the condenser. Reduced time and labour result in increased capacity.

-

Turbodistillation is an improved version of the water and steam distillation allowing faster extraction from hard-to-extract materials (bark, root, seeds). Plants are soaked in water and the steam is circulated through this mixture (the same water is continuously recycled during the process).

-

Hydrodiffusion is a procedure where the steam at athmospheric pressure is passed into the plant material from the top of the distillation still. Tube type condenser is placed under the plant holding basket and steam can saturate the plants more evenly and in less time than with steam distillation. The essential oil smells much more like the original plant.

-

Continuous steam distillation : the chopped plant material is conveyed by a pneumatic system or an endless screw into the distillation still body. Within the still it is brought into contact with superheated steam and essential oil is extracted from the plant material.

Structure of the mobile distillation equipment: distillation yard (a), container full of plants during distillation (b), essential oil separator (c), empty container with steam pipes (d), traction of the mobile container (e) (Photos: Pluhár, 2012)

Continuous steam distillation unit (Photo: Pluhár, 2006)

After distillation, the essential oil usually contains undesired contaminants: floating particles and water. During post-distillation procedures, settling filtration and dehydration are necessary. In order to dehydrate the essential oil, redistillation or refining is applied. After cleaning, the essential oil can be stored in closed stainless steal or dark coloured glass vessels filled to repletion, to prevent deterioration by light and air.

Cold pressing

Cold pressing is a widely used ancient method of extracting the essential oils/vegetable oils by mechanic pressing of the plant parts on ambient temperature. Nowadays improved industrial scale methods of this conventional technic are used. Its application is advantageous in the case of easily available oils found in quite high amount (e.g. in superficial glands) and at thermosensitive compounds, where the distillation would result in thermodegradation or unwanted transformations at 100°C. Frequently used at Citrus spp.: bergamot, lemon, orange, grapefruit and mandarin. Olive oil and other vegetable oils rich in unsaturated fatty acids are also effectively obtained by cold pressing.

As a first step of the extraction of Citrus peels, the essential oil is obtained by scarification, while the peels are rolled over a sharp projection that penetrates the peel. This process is followed by squeezing the juice from the peel by mechanic pressing. Under a spray of water the essential oil is trapped in an emulsion, and then the emulsion is collected in a tank. Solid particles are removed in the next step by filtration and finally the essential oil is separated by centrifugation from waxes, pectin and cellulose.

Structure of orange peel (a) with lysigenic essential oil ducts (b)

Solvent extraction

Solvent extraction is the most widely used modern extraction method suitable for isolation of compounds of different chemical structure. Different kinds of solvents can be used during the procedure:

-

organic solvents with low boiling point (propane, butane, hexane, methanol, ethanol, 2-propanol, aceton, dichloro-methane, petrolether),

-

cold, superheated or boiling water,

-

waxes and fats

-

liquified fluid solvents: carbon dioxide, etc.

Procedures can be divided into cold or heated (40 oC<) solvent extractions. Appropriate selection of solvent highly influences the quality and yield of the extract. The ideal solvent has high selectivity, low viscosity, high solvating power, low boiling temperature, stability and neutral character. Moreover, it is non-toxic and accepted for foods, readily available in large quantities, recoverable, easily removable leaving no solvent residue, non-flammable, inexpensive and environmentally friendly.

Types of solvent extraction are the extraction with organic solvents, with cold or melted fats (enfleurage), with hot or warm fluids (maceration) and ultrasonically assisted solvent extraction. As raw material, fresh or dried plant parts are used.

During the essential oil extraction with organic solvents, the production of ’concrete’ is the first step. After the plant material has been prepared, it is loaded into a tank and mixed with an apolar solvent (e.g. hexane). As a result of the process, extractables (essential oils, fats, waxes and pigments) become resolved, then the solvent is evaporated at reduced pressure. The remaining product is called ’concrete’, having waxy character, such as the jasmine concrete containing as much as 55% essential oil.

Generally, the next step of the procedure is the production of ’absolute’, when the concrete is reextracted with polar solvent (alcohol), by mixing it with pure ethanol. As fatty acids and waxes are not alcohol soluble materials, they can be removed during a stepwise refinement, which result in a highly concentrated, viscous liquid. The final product („absolute”) is rich in essential oil (10-55%) but also contains 5% ethanol, small amount of waxes, traces of apolar solvent (hexane), etc.. In the case of rose, jasmine and orange blossom, absolute is always in demand and applied by perfumery and cosmetic industries. 100 kg fresh rose petal is necessary to 1 kg rose absolute, while 8 million pieces of jasmine flower are used to obtain 1 kg jasmine absolute.

Equipment applied for solvent extraction of medicinal and aromatic plants (Source: http://image.made-in-china.com )

Jasmine absolute ( http://www.florame.co.uk )

Enfleurage (pomade preparation)

Enfleurage is an extraction method which uses vegetable and animal cold fats to extract fragrance from blossoms. The procedure needs high labour intensity, however, perfumery industry requires valuable, special flowers containing delicate fragrances, which are available only in very small amounts (e.g. jasmine, tuberose, violet, rose). This is the reasonable method of extraction of these flowers as if they were subjected to distillation or solvent extraction, valuable compounds would be destroyed.

Freshly collected flowers are placed onto trays containing a fat or lard layer, then trays are stacked on top of each other to keep out the air and stored in wooden frames. The fat layer remains for 1-60 days, while the flowers are changed by freshly picked ones, in different intervals specific for the plant species (e.g. jasmine: in 12-30 hours; tuberose: in 24-100 hours). The process is repeated 24-36 times until the fat is fully saturated with the essential oil. Saturated base material is then scraped from the trays and the resulted product is called ‘pomade’. Pomade is carefully melted at low temperature then filtrated, extracted with alcohol to remove unwanted materials (e.g. waxes, pigments, fat). Finally, alcohol is evaporated by distillation at low temperature and pressure and the remaining product is the ’absolute’.

One ton of fresh jasmine flower is necessary to obtain 1 liter absolute by enfleurage.

Enfleurage (pomade procedure) (Source: http://parfum4.e-monsite.com )

Maceration

During the maceration process, warm or hot liquids (water, oils or melted fats) are used to extract plant compounds by soaking then agitating the plant and solvent together. This is a time-consuming procedure, while temperature of the solvent has to be kept warm. After the extraction has been completed, the system is cooled down; the plant parts are separated from the extract by filtration and centrifugation.

This is the traditional way of preparation of ’St. John’s Wort oil’ by using vegetable oils. The fresh flowers are absorbed in the oil and the valuable compounds are open-air extracted in summer by using solar energy. Red colouration appeared after several weeks because hypericin and hyperforin derivatives absorbed in the oil together with the phenolic compounds.

Nowadays more developed solvent extraction methods are used instead of maceration.

Traditional way of the extraction of ’St. John’s Wort oil’ by using vegetable oils for maceration (Source: http://www.wisemountainbotanicals.com )

Ultrasonically assisted extraction (sonication)

Sonication has been developed in order to increase the efficacy and speed of solvent extraction, while the plant is placed into the solvent and treated by ultrasound of 20-500 kHz frequency as well.

The milling degree of the plant material determines the extraction level: intensifies the mass transfer and improves the the penetration of the solvent into the cell and reduces the time of diffusion process. In some cases the extraction time could be decreased 30-fold if compared to the conventional solvent extraction. Typical solvents applied during sonication are petrolether, water and the water-alcohol mixture.

Essential oil glands can easily be destroyed by sonication and allow to rinsing of the cell content, especially if the plant has been pulverized prior to extraction. In the case of saffron, the pigments of stigma can be extracted more efficiently by ultrasonic extraction than it is specified by the standard (an extraction by cold water). In the latter case, the pulsing ultrasonic treatment with short intervals was more effective than continuous sonication.

Extraction of saffron pigments by sonication (Source: http://www.bulkinside.com/news/ultrasonic-assisted-saffron-extraction )

Supercritical fluid extraction (SFE)

Supercritical fluid extraction (SFE) is an industrial scale extraction procedure applied worldwide for obtaining bioactive plant compounds, principally for pharmaceutical and food industrial purposes.

In the course of supercritical fluid extraction, the plant material is extracted by using a solvent of fluid state (e.g. by fluid carbon dioxide). Supercritical phase is a special physical condition of gases or liquids, when both their pressure (p) and temperature (T) exceed the specific critical points. The fluid state is a transitional phase between gas and liquid, where the extracting power of the solvent increases extraordinarily, which improve the efficacy of the extraction.

Supercritical fluid extraction is an environmentally gentle process, which results in solvent-free end-products having significant advantage in food and pharmaceutical industries, either. Efficacy of SFE depends on the adequate selection of extraction pressure, temperature, duration as well as the quality of solvent/co-solvent used. The procedure is generally quick and inexpensive, though the installation of the pressure proof equipment is rather costly, requiring high capital expenditure.

The most frequently used solvent of SFE is fluid CO2, which has many advantages. It is not harmful to human health, thus, appropriate for creating medicines, foods and consumer goods (e.g. tea, coffee). In fluid state its density is high, solving properly a great number of substances (mainly apolar ones). Easily available in high purity and high quantity but non-reactive, thus, it does not affect the other elements of food. Having low critical temperature (31°C) and low critical pressure (73 atm/bar), one can work with it at low temperature, while the substance does not suffer a loss. After the extraction, CO2 quit the extract without any residue and is capable for recycling.

SFE-CO2 can be applied for extracting plant substances of small, volatile molecules of apolar character (e.g. essential oils, fatty oils, steroids, volatile alkaloids, etc.), but suitable for many other compounds by adding modifiers (entrainers, co-solvents). In industrial scale, SFE is used to extract active compounds, flavours, oleoresins of various spices, plant pigments (paprika, alkanet, etc.), for decaffeination of coffee and tea as well as to preapare extract of hops, which is indispensable for brewery.

It was proven in a number of cases that extracts rich in essential oil can be obtained by SFE in a considerably shorter time than by hydrodistillation. The odour and taste of these extracts are reminiscent of those of the intact plant, as the thermosensitive volatile compounds are not destroyed during the process. The compound spectra of the essential oil rich SFE extracts are usually much wider than those of the respective distillates, however, further non-volatile compounds may also appear in them. It was also verified that SFE can be an appropriate method to obtain medicinal plant extracts enriched in bioactive compounds (e.g. in the case of Hypericum, hyperforin rich extract can be obtained, used for manufacturing antidepressants).

Industrial scale equipment applied for supercritical fluid extraction of medicinal and aromatic plants (Source: http://www.natex.at/indusextractionplants.html )

Quantitative and qualitative features belonging to optimized SFE parameters of savory ( Satureja spp.) and thyme (Thymus spp.) drugs (after Kutta et al . 2005, 2007)

(Legends: HD: hydrodstilled essential oil; SFE-CO2: supercritical fluid extract obtained by using carbon dioxide)

|

Features |

Saturejae herba |

Saturejae montanae herba |

Thymi pannonici herba |

Thymi vulgaris herba |

||||

|

Method of extraction |

SFE-CO2 |

HD |

SFE-CO2 |

HD |

SFE-CO2 |

HD |

SFE-CO2 |

HD |

|

Extract yield, % |

0.15-0.78 |

<1.14 |

0.43-1.51 |

<1.56 |

0.15-0.68 |

<1.14 |

0.21-1.42 |

<1.70 |

|

Max. extract yield, % |

0.78 |

1.51 |

0,68 |

1.42 |

||||

|

Parameters optimized for max. yield |

27 MPa 30 min/40 oC |

60 min 10 MPa/40 oC |

16 MPa 30 min/40 oC |

22 MPa 30 min/40 oC |

||||

|

Number of volatile compounds |

20 |

>4 |

27 |

>3 |

25 |

> 8 |

25 |

>12 |

|

Proportion of carvacrol/thymol (max. %) |

81.94 |

>54.84 |

66.91 |

<78.88 |

60.47 |

<64.27 |

67.49 |

<69.91 |

|

Parameters for max.carvacrol/thymol ratio |

26 MPa 30 min/40 oC |

14 MPa 30 min/40 oC |

19 MPa 30 min/40 oC |

60 min 10 MPa/40 oC |

||||

STORAGE OF MEDICINAL PLANT PRODUCTS AND THEIR TRADING POSSIBILITIES

End-products are stored for shorter or longer periods before sale, or delivery. In the warehouses the following parameters are strictly controlled: temperature (cannot be more than 25°C), air-humidity (maximum 60%); the place need to be kept clean and be protected against pests.

Storage of herbal products in a modern warehouse (photo: Sárosi, 2012)

Obviously herbal products cannot be stored indefinitely; the shelf-life is basically determined by the active constituents of the drug as well as the storage conditions. Generally the herbal products need to be consumed within one year, however, the possible elongation of this time period is necessary to be evaluated focusing on the different drug types. For this purpose stableness analysis is usually carried out in every 3 month of the storage during 2-3 years. During this analytic work quality parameters described by the pharmacopoeias or other standards and specifications are analysed in each case. Similarly to chapter 9.1.2., the results are grouped according to the main active constituents.

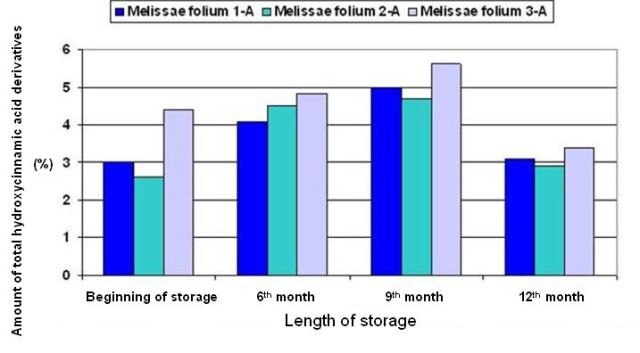

Drugs containing gylcosides are extremely sensitive to the air-humidity, thus this parameter needs to be maintained as low as possible during the storage. Among phenoloids tannins can oxidize easily; they are transforming into phlobaphenes; which constituents do not have any biological or pharmaceutical effects. With relevance to flavonoids during the storage their amount continuously decreases in the case of chamomile flowers; after 9 months significant quality loss occurs. The same tendency can be seen referring to the hydroxycinnamic acid derivatives, detected in the leaves of lemon balm.

Changes of the apigenin-7-O-glucoside content in chamomile flowers during one year of storage

|

Months of storage |

Chamomile flowers |

Chamomile filter tea |

|

Apigenin-7-O-glucoside content Mean ± standard deviation |

Apigenin-7-O-glucoside content Mean ± standard deviation |

|

|

0 |

0.18 ± 0.02 |

0.32 ± 0.01 |

|

6 |

0.13 ± 0.02 |

0.33 ± 0.01 |

|

9 |

0.27 ± 0.02 |

0.32 ± 0.01 |

|

12 |

0.07 ± 0.02 |

0.28 ± 0.02 |

|

p value |

0.0000 |

0.0000 |

Changes of the hydroxycinnamic acid derivatives in the leaves of lemon balm during one year of storage

Fatty acids can also oxidize easily, therefore natural or synthetic antioxidants are usually added to the oils (e.g. borago or pumpkin seed oils); the final products are taken into dark coloured bottles and stored at low temperature. Nitrogen containing alkaloids are the less sensitive active compounds to the conditions of storage, therefore drugs containing alkaloids as main compounds, are able to be stored for longer periods without significant quality loss.

On the contrary to alkaloids, referring to the terpenoids, essential oil compounds are rather sensitive to the way and length of storage. Since essential oils are completely evaporating at room temperature, the European Pharmacopoeia (Ph.Eur., VII.) gives special requirements with relevance to their storage: essential oils need to be stored in a container made of glass or stainless steal, protected from sunlight, oxygen and heat, maintaining not more than 25°C (in certain cases 20°C) in the warehouse.

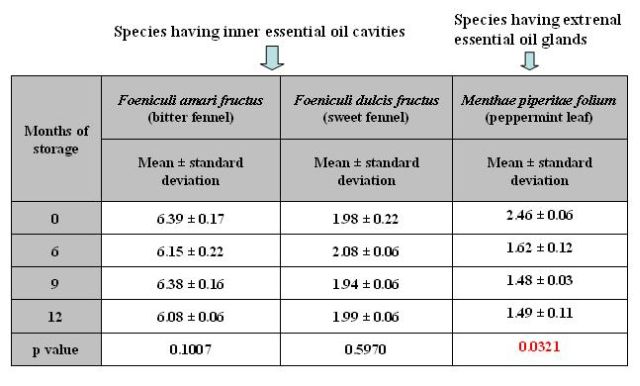

Plants can contain essential oil in essential oil glands (external) and in essential oil cavities (internal). Depending on the way of accumulation the sensitiveness of the different plant parts can be variable. Essential oil glands can be damaged easily; therefore these drug types are much more sensitive not only to the way of the primary and secondary processing, but also to the general conditions of storage. Improper processing can results in significant essential oil lost. In the inner essential oil cavities the active compounds are more protected, thus seeds, fruits and roots are less sensitive, and are usually able for longer storage.

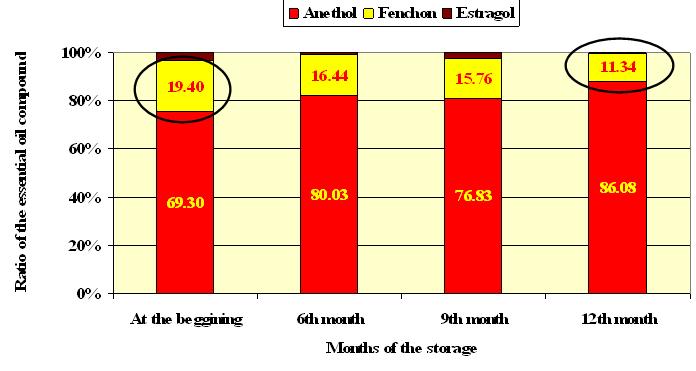

Changes of the essential oil content in different drug types during 1 year of storage

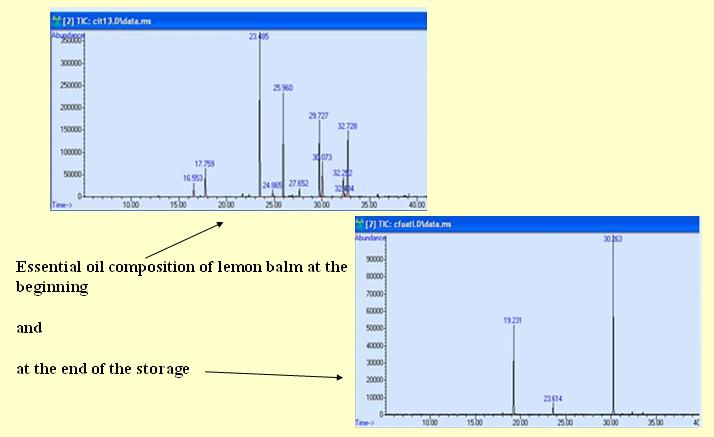

However, not only the amount of the essential oil is affected by the length and way of storage; its composition can also change significantly. During the storage the ratio of low molecular weight monoterpenes decreases, while the proportion of sesquiterpenes, having bigger size and molecular weight, increases. Therefore, after a certain time, the essential oils become viscous, their colouration will be darker, and finally their typical smell disappears. In certain cases these disadvantageous changes define the shelf life of a product, and not the possible essential oil loss. In figure the changes of the essential oil composition can be seen during the storage of bitter fennel. Its bitter taste is due to the presence of fenchone in the essential oil, therefore the ratio of this active compound determinates the quality of the drug. According to the European Pharmacopoeia (Ph. Eur. VII), the ratio of fenchon cannot be less than 15% in the essential oil; looking at the figure we can see, that after the 9th month, the drug did not meet this requirement.

Chromatograms of lemon balm’s essential oil at the beginning and at the end of storage (after 1 year)

Changes of the essential oil composition of bitter fennel during 1 year of storage

After the secondary processing the end-product can be delivered. The regulations referring to the marketing of herbal products have been significantly changed recently in the European Union (Directive 2001/83/EC).

Sinupret forte – a well-known herbal medicinal product of Bionorica

New categories were formed, such as herbal medicinal products. In this case the products must be manufactured according to Good Manufacturing Practice (GMP) to ensure good quality and safety. “Herbal medicinal products are defined as any medicinal products, exclusively containing as active ingredients one or more herbal substances or one or more herbal preparations, or one or more such herbal substances in combination with one or more such herbal preparations. A good example for this category is Sinupret (made and distributed by Bionorica Gmbh.). Within this group the EU legislation classifies as traditional herbal medicinal products those herbal medicinal products that have been used “at least 30 years, including at least 15 years within the EU, are intended to be used without the supervision of a medical practitioner and are not administrated by injection”.

“Simplified registration procedure is intended for herbal medicinal products with a long tradition, which do not fulfill the requirements for a marketing authorization, in particular those requirements whereby an applicant can demonstrate by detailed references to published scientific literature that the constituent or the constituents of the medicinal products has or have a well-established medicinal use with recognized efficacy and level of safety (so-called "well established use"). In both cases National Drug Institutions are responsible for the authorization.

Since the establishment of GMP is rather expensive, and the registration of herbal medicinal products is a long and difficult process, herbal products containing medicinal plants or natural originated active compounds will be mainly registered as foods – as dietary supplements. Food supplements contain nutrients or other substances concentrated, and the purpose of their usage is to supplement the normal diet. They are marketed as tablets, pills, capsules, liquids in measured doses etc. Details about their marketing and registration can be seen on the following web-site: http://ec.europa.eu/food/food/labellingnutrition/supplements/index_en.htm. Since dietary supplements are not medicines, they cannot be labelled with drug claims, only with health or nutrition claims. The products need to be registered by the National Food Institutions, only their safety (dosage and purity) is necessary to be demonstrated. Because of the easy registration up to nowadays more than 8000 dietary supplements have already been registered in Hungary. Most of them are purchasable in drugstores, or can be ordered on different web-sites. Their continuous consumption is rarely reasonable, especially, if one of the constituents is a medicinal plant or natural originated active compound.

A well-know traditional herbal medicinal product marketed in the European Union (http://www.schwabepharma.co.uk/pages/products/kaloba-tablets.php)

Creams containing natural originated substances can be registered as cosmetics (at the National Food Institutions) or as therapeutic supplements.

The EU carries on a uniform policy, namely, if a member country registers a product, the other countries must accept it without additional conditions.

Control questions

Right answers

Literature cited:

-

Anonymus (2003): Pharmacopoeia Hungarica. Ed. 8th. Vol.4/B. Budapest, Medicina Könyvkiadó.

-

Argyropoulos, D., Müller, J. (2011): Effect of convective drying on quality of lemon balm (Melissa officinalis L.). Procedia Food Science 1: 1932-1939.

-

Asami, D. K., Hong, Y. J., Barrett, D. M., Mitchell, A. E. (2003): Comparison of the total phenolic and ascorbic acid content of freezedried and air-dried marionberry, strawberry, and corn grown using conventional, organic and sustainable agricultural practices. Journal of Agricultural and Food Chemistry, 51: 1237–1241.

-

Dachler, M., Pelzmann, H. (1999): Arznei- und Gewürzpflanzen. Österreichischer Agrarverlag. Klosterneuburg. p. 115-125.

-

Fu, H. Y. (2004): Free radical scavenging and leukemia cell growth inhibitory properties of onion powders treated by different heating processes. Journal of Food Science, 69: 50–54.

-

Harbourne, N., Marete, E., Jacquier, J. C., O’Riordan, D. (2009): Effect of drying methods on the phenolic constituents of meadowsweet ( Filipendula ulmaria) and willow (Salix alba). LWT - Food Science and Technology, 42: 1468–1473.

-

Karabulut, I., Topcu, A., Duran, A., Turan, S., Oztruk, B. (2007): Effect of hot air drying and sun drying on color values and β-carotene content of apricot (Prunus armeniaca L.). LWT 40: 753-758.

-

Keinanen, M., Julkunen, T. R. (1996): Effect of sample preparation method on birch (Betula pendula Roth) leaf phenolics. Journal of Agriculture and Food Chemistry, 44: 2724–2727.

-

Kutta, G., Pluhár, Zs., Sárosi, Sz. (2007): Yield and composition of supercritical fluid extracts of different Lamiaceae herbs. International Journal of Horticultural Sience, 13 (2): 79-82

-

Kutta G., Pluhár Zs., Héthelyi É. (2005): Különböző eredetű kakukkfű fajok (Thymus spp.) desztillált és szuperkritikus szén-dioxid extrakcióval kinyert kivonatainak összehasonlító értékelése. Olaj, Szappan, Kozmetika, 54 (4): 180-186.

-

Mulinacci, N., Innocenti, M., Bellumori, M., Giaccherini, C., Martini, V., Michelozzi, M. (2011): Storage method, drying processes and extraction procedures strongly affect the phenolic fraction of rosemary leaves: An HPLC/DAD/MS study. Talanta 85: 167-176.

-

Páramo, D., García-Alamilla, P., Salgado-Cervantes, M.A., Robles-Olvera, V.J., Rodríguez-Jimenes, G.C., García-Alvarado, M.A. (2010): Mass transfer of water and volatile fatty acids in cocoa beans during drying. Journal of Food Engineering 99: 276-283.

-

Pellati, F., Bruni, R., Bellardi, M. G., Bertaccini, A., Benvenuti, S. (2009): Optimization and validation of a high-performance liquid chromatography method for the analysis of cardiac glycosides in Digitalis lanata. Journal of Chromatography A. 1216: 3260–3269.

-

Siriamornpun, S., Kaisoon, O., Meeso, N. (2012): Changes in colour, abtioxidant activities and carotenoids (lycopene, β-carotene, lutein) of marigold flower (Tagetes erecta L.) resulting from different drying processes. Journal of Functional Foods, 4(4): 757-766.

-

Terrill, T. H., Windham, W. R., Evans, J. J., Hoveland, C. S. (1990): Condensed tannin concentration in Sericea lespedeza as influenced by preservation method. Crop Science, 30: 219–224.

-

Yaldiz, G., Ozguven, M., Sekeroglu, N. (2010): Variation in capsaicin contents of different Capsicum species and lines by varying parameters. Industrial Crops and Products 32: 434-438.

-

Zámbó I., Lenchés O. (2000): Gyógynövények feldolgozása – minőségi drog előállítása. In: Bernáth J. (Ed.): Gyógy-és Aromanövények. Budapest, Mezőgazda Kiadó. pp. 97-121.